Drinking production. Production of bottled water. Business idea: production of bottled water. We plan the timing of preparations for the opening

Such equipment is capable of producing ozonation from 50 to 500 liters of drinking water per hour. It is a single housing that does not require special installation. The technology does not consist in carbonation, but in filling drinking water with oxygen at the ionic level. The output is a liquid that contains 40 mg per 1 liter of dissolved oxygen.

Ozonation of mineral bottled drinking water in production is carried out immediately before bottling into containers. The ozone level in such liquids is 0.2-0.3 mg/l. They can be usable for quite a long time.

Ozonation occurs in a very short time, but nevertheless, it allows you to disinfect the product and the container. Ozone also affects the bottling system itself, the cap, the neck of the bottle and other elements involved in the process. After the bottle is hermetically sealed, the ozone molecules turn into oxygen. This process renders the product practically sterile prior to consumption. Ozonation is mainly applied at the last technological stage.

In the end, it should be noted that on average in the industry, the production of drinking mineral bottled water has a profitability of about 30%. With such an indicator and subject to the full sale of products, the investment promises to pay off within 12 months. The term, accordingly, will increase if more expensive equipment is purchased and the production premises are bought out.

What equipment to choose for the production of mineral water

To organize a small production of mineral water, a novice entrepreneur needs to purchase special equipment. Depending on the available finances, this may be new or used equipment. There is also the option of purchasing each machine separately or purchasing a ready-made automated production line. For the production of mineral water, you need to buy the following elements: - borehole pump; - coarse and fine filter units or an automatic system; - bottle production equipment; - water tanks and tanks ;- machine for filling and corking bottles;- apparatus for the production of labels.

Mineral water production technology

The mineral water production technology consists of several stages. During the production process, water undergoes some treatment. Mineral water is pumped out by special pumps from wells 300-400 meters deep and lifted into storage tanks. Then the water enters the filter unit, where it is cleaned with filtration materials in two stages - coarse and fine cleaning, and is also disinfected with ultraviolet rays. Before filling the mineral water with CO², it is pre-cooled on a plate heat exchanger. After that, on a special production line, carbon dioxide is saturated, the solubility of which in water depends on temperature and pressure. The preforms prepared in advance are fed into the machine for the production of bottles, where they are heated and the containers are shaped under pressure. At the last stage, mineral water is poured into PET bottles, corked with plastic stoppers, and a marked label is glued on. Finished products are packed in shrink film in 6 pieces, stored or immediately delivered to customers.

For the production of drinking water, leading suppliers use two types of natural resource:

- Natural water extracted from environmentally friendly sources;

- Natural water purified using special equipment or water treatment systems.

The general scheme for the production of drinking water is shown in the figure.

The production of water purified in the water treatment system includes the following stages of the technological process:

1. Extraction of water from a well, which is carried out using a special submersible pump and an underground pipeline. Thanks to special equipment, water is supplied to the water treatment area in a special large-capacity tank.

2. Water purification is carried out in several stages:

- rough mechanical cleaning - allows you to remove large mechanical impurities from the water with a size of about 400 microns;

- fine water purification - purifies a natural resource from suspended impurities with a size of at least 1 micron;

- disinfection of water by modern methods - can be carried out using ultraviolet radiation, chlorination or ozonation.

After monitoring the chemical composition of water, the natural resource enters tanks made of stainless steel. By means of storage tanks, continuous production of drinking water is ensured.

3. Bottling of drinking water - is carried out on a specialized line, where the natural resource enters into separate containers of the required volume. As a rule, in factories, bottling of water takes place on an automatic machine, without the participation of people.

4. Containers with water are sealed and sent to the finished product warehouse. In order to protect products from fakes and to mark the type of water, leading manufacturers put shrink caps of different colors on containers.

How bottled water is made. bottled water

Recently, more and more people are beginning to understand that drinking tap water is not entirely correct, since such water contains quite a lot of foreign impurities that do not have the best effect on health. For this reason, water bottled in plastic bottles at the factory (bottled) has become quite popular. For water to be considered bottled, it must meet certain chemical and physical requirements.

As a container for bottled water, plastic or glass containers with a volume of 250 milliliters to 22 liters are used. The composition of bottled water cannot include any additional elements (flavoring additives, food colorings, etc.), the calorie content of such a product cannot exceed zero percent.

Bottled water is divided into the following types according to its composition:

- Mineral.

- Artesian.

- Purified or distilled.

- Spring or well.

Benefits of bottled water

As the main advantage of bottled water, one can single out the indicator that it does not contain any harmful impurities in its composition. Water, before being poured into special containers, is cleaned in accordance with current regulations.

Another advantage of bottled water is the fact that it is bottled in containers of various volumes and you can take as much water with you as you need without the need for additional purification. And if you find some promotions (for example, like here https://www.truewater.ru/aktsii/), then you can also save on such water.

Disadvantages of bottled water

One of the main disadvantages of bottled water is that during the purification process, it is deprived not only of harmful substances, but also of beneficial minerals. In addition, it is practically impossible for an ordinary consumer to check the quality of bottled water and one has to rely on the honesty of the manufacturer.

Today it is possible to organize a business in almost any type of activity. It is not necessary to immediately open a large production. You can start with a small workshop. For example, the production of drinking water is not an extremely difficult task, although it requires patience, care and work.

Advantages and features

I must say that this business has its advantages:

High payback;

Possibility of expansion;

High demand for quality products.

Naturally, the production of drinking water is not without drawbacks. For example, you will have to raise an impressive amount of start-up capital, since you cannot do without expensive equipment. In addition, you will need to constantly deal with the sanitary and epidemiological service, which controls the quality of the water. However, a properly organized business can bring high income. Naturally, for this you first need to outline a business plan, decide on the sales market and other nuances. It is important to consider the level of competition.

Be sure to decide what type of activity you will be engaged in. That is, you can sell water from your well that needs to be drilled; engage in bottling and supply of foreign water to the markets of the city. At the same time, you must also decide on the method of extracting water. It can be key or extracted from the tap and cleaned with ultra-modern filters.

What documents are needed?

Now consider the question of what, in fact, is needed in order to open the production of drinking water:

1. Certificate of a private entrepreneur.

2. Charter of the company.

3. Conclusions of security authorities (fire service and SES) on the compliance of your equipment with all established standards.

4. Certificate that the quality of the water used in production fully meets all state requirements (also issued by the sanitary and epidemiological service).

5. License for entrepreneurial activity. To do this, of course, you will have to collect documents such as a lease agreement for premises and equipment, all your personal data certified by a notary.

In principle, these documents are quite enough to open the production of drinking water. Naturally, you will need a bank account. In addition, it is required to draw up agreements with suppliers of water (if you do not extract it yourself), containers and other consumables.

Features of the choice of premises and staff

Opening the production of drinking water is not very difficult. Much harder to keep him afloat. For work, you will definitely need a room (workshop) that is of sufficient size, all-round access. Naturally, the building must have a supply of all necessary energy sources, a telephone line, and the Internet.

It is desirable that the room was renovated and not old. Pay special attention to the quality of electrical wiring. The fact is that the production of bottled water requires the use of a large amount of equipment.

The building will need to be divided into several parts: a site where water will be extracted, a liquid purification room (multi-stage), as well as its spill. In addition, you will need rooms for staff, where employees can change clothes, have lunch, and relax. A warehouse is required for finished products. Naturally, each room must meet sanitary standards.

What equipment is needed for work?

The production of bottled water takes place with the help of complex and rather expensive mechanisms. Their number depends on your financial capabilities and the scale of the business.

The production of bottled water takes place with the help of complex and rather expensive mechanisms. Their number depends on your financial capabilities and the scale of the business.

So, for work, the following equipment is required for the production of water:

Mechanisms by which the extracted liquid is purified;

Machines for pouring water.

If you want to reduce the cost of production, you can purchase a machine for the manufacture of plastic containers, in which you will package the liquid. However, this is not at all necessary. You can conclude an agreement with suppliers of plastic bottles. Moreover, in any case, you have the ability to adjust the amount of packaging.

Today, you can buy a whole automated production line for the drinking water bottling shop, which consists of all the necessary blocks. However, such equipment should be purchased if you see prospects for further business expansion.

What quality should the product have?

Water is an essential element for the body, just like air. Naturally, it must meet the highest quality requirements and international standards. Before organizing the production of drinking bottled water, it should be borne in mind that it must be harmless and safe in chemical composition. In addition, the liquid should not have an increased background radiation or contain harmful bacteria and microorganisms that can cause various kinds of epidemics.

Consider the criteria for water quality in more detail. So, the liquid should not contain dangerous and harmful substances that may appear as a result of its extraction and processing. Also note that not all water sources are safe to drink. That is, a well should be drilled where there are deposits of the maximum clean liquid.

Water must be taken for analysis by the sanitary and epidemiological service. After that, you will receive a response with a detailed description of the substances and compounds contained in the liquid, as well as their quantity. It should be noted that the source should not be contaminated with any mechanical debris. Be sure to make sure that there are no living organisms in the water. Otherwise, your products will quickly deteriorate and can harm your health.

Manufacturing technology

In order for you to get a finished product, you need to go through several stages. The production of drinking bottled water begins with the receipt of raw materials.

In order for you to get a finished product, you need to go through several stages. The production of drinking bottled water begins with the receipt of raw materials.

To store it, you will need large tanks made from environmentally friendly materials. After that, the liquid must undergo multi-stage purification:

Mechanical. Moreover, it is carried out in 2 stages: coarse (impurities of 450 microns in size are eliminated) and fine, due to which the smallest particles of debris are removed from the water.

Chemical. Produced using the latest technologies and materials. Combined methods are used here: chlorination (the most common), ultraviolet or ozone treatment.

Now the prepared water can be poured into containers. This happens on an automated line that does not require human intervention. Additionally, you can enrich your products with oxygen.

Manufacturers and suppliers. There are 110 companies in the 2020 catalog. Production and wholesale. Table water plants included in the list of the exhibition:

- GC "Alonka";

- KavMinVody;

- OOO "Fonte Aqua";

- Group of companies "Slavda";

- Soyuz Food Products LLC;

- Factory of soft drinks "Tonus", etc.

The products of the manufacturer "Achaluki" are also popular. Enterprises extract water from wells in ecologically clean regions of the republics, territories and regions of Russia. Drinking mineral and spring water in Russia is traditionally used to improve health and treat chronic diseases of the stomach and duodenum. Therapeutic and prophylactic properties are confirmed in water from Zheleznovodsk, Essentuki. Crimean sources of mineral and table waters are known. Products are bottled, PET containers and glass. Possibility of filling into containers of large volume under the order.

New trademarks and product names are introduced to the market. Production contact information - address, phone, website in the "Contacts" tab. Delivery across Moscow and the Moscow region, regions of the country and the CIS transport organizations. Leave feedback about the service and purchases!

We invite suppliers of bottles, health facilities, dealers, pharmacies to cooperate. To buy in bulk, download the price list - contact the manager. Prices for large wholesale are negotiated by phone individually!

The availability of water from a tap in your apartment or from a well in a rural area is not always an indicator of the availability of a quality liquid that can be consumed in its pure form without additional processing. Unpleasant smell, color and taste are the least evil that awaits people when trying to quench their thirst. Perhaps the presence of microbes, viruses that cause dangerous diseases. Therefore, many today do not want to drink homemade water, believing that the bottled version is safer. The demand for liquid from a store or from a manufacturer is growing and giving grounds for citizens to think about how to open the production of drinking water from scratch? The competition is tough, but there is an opportunity to make money if you approach the matter in the right way. Our step-by-step instructions will allow you to understand how to start a business on the water, what documents to collect, how much money and effort to invest.

How to organize

This business idea for many will seem simple and easy to implement. He received permission to sell water from a specific source, passed it through a purification system, poured it into a bottle and sent it to store shelves. But it's not. Water is a product to which the special attention of regulatory authorities, especially SES, is riveted. If the liquid does not meet the content requirements, then the consumer will never see it.

Before equipping the production area, you need to find a source from which water will be drawn. The sample is sent to a laboratory for analysis. After a positive conclusion about the quality, you can get permission to use it to obtain water that will reach the buyer.

The opening of production is possible after determining the type of source:

- Through the tap of the water utility, crashing into the overall system.

- Drilling my own well.

- Having found a spring or a key with good water in sufficient volume.

The entrepreneur chooses his option and begins collecting documents for the implementation of the project. It may take a lot of time.

What documentation will need to be collected

Having chosen the source of extraction of raw materials, we draw the liquid into a container and take it to a private or public laboratory. We find out the quality of water, the presence of microorganisms, harmful substances. The conclusion will show how difficult the next stage of purification and enrichment of the product with useful additives will be. If the composition does not meet your needs, you need to continue searching for a source or conclude a contract for the supply of raw materials from a trusted source of raw water.

- We conclude an agreement with a partner or obtain permission to drill our own well.

- We turn to the energy company to sign an agreement on the use of a separate line for the production of water.

- We receive the conclusion of the SES on the condition of the premises, the compliance of the equipment with sanitary requirements (the absence of materials that emit harmful substances that can enter the water during processing and bottling).

- Ready-to-drink water will also have to receive a separate quality certificate from the SES after the start of production. Inspections will be carried out frequently and at every stage of the activity to ensure that no violations occur.

- Lease agreement for the premises in which the production will be located. If the building is owned, then proof must be submitted.

- Documents on the legality of business are drawn up at the Federal Tax Service, where, after registration, a certificate of an individual entrepreneur or LLC is issued. You choose the form of registration yourself, taking into account personal circumstances. Do not forget to indicate the type of activity according to OKVED. In our case, we choose No. 11.07 - "Production of soft drinks, various bottled drinking water."

- The conclusion of the fire department on admission to the production of water in the selected room will be required.

This is the main list of documents that will have to be collected to start water production and further work.

Project Specifications

In order for the water to be of high quality in taste and composition, you need not save on the premises and its equipment. Typically, production is located next to a well, a crane or other source of raw materials. Some manufacturers opt for the method of separately transporting raw water to a treatment facility and bottling it. The equipment must have a modern multi-stage filtration system to eliminate the risk of obtaining an incompletely purified product. This can contribute to the rapid deterioration of water, the appearance of a musty smell. It is better to choose a full-cycle automatic line from filling raw materials to bottling.

At the initial stage, you should not spend money on additional enrichment of water with salts, minerals, gas, sweeteners. It is necessary to understand whether production in the region is profitable and whether it can compete with other companies. The room should have enough space for the workshop, staff rooms, administrative sector, storage areas. The workshop must be clean and sterile. Therefore, it does not hurt to make cosmetic repairs. Raw materials must be stored in special containers that are tightly closed and do not react when in contact with water.

A separate issue is the supply of containers. Many entrepreneurs make plastic containers on their own, buying special equipment for blowing bottles from blanks. This eliminates the risk of microbes entering the container and makes it possible to choose the shape and color of the water packaging.

The cost of equipment depends on the configuration and manufacturer. There are many offers on the market. It is worth considering what a small business for the production of water is aimed at - small batches of drinking water without gas or a multidisciplinary workshop (carbonated water, mineral, sweet, medicinal). But saving on equipment of the production line is not worth it. Do not forget about consumables (filters and other devices) that need to be changed in a timely manner so that the water quality does not decrease.

Positive and negative aspects of the enterprise

In any business, there are pros and cons that you need to see in advance and try to find your benefit. Let's note the most noticeable shortcomings in this segment of small business:

- Dependence on supervisory authorities. SES controls the quality of water, forcing them to take samples for analysis. If the quality decreases or microbes, viruses are found, production will be closed until the problems are fixed.

- Tough competition. With a wide range of products in stores, from famous brands to little-known ones, it is not easy to find your place.

- The need to find raw materials that would not require a large number of purification steps. Water should be to the taste of the consumer (such sources are not available in every region).

- The high cost of equipment can be overwhelming for a young entrepreneur if an investor cannot be found.

- For large-scale production, large areas are required, which are not always within the boundaries of the settlement. The farther away the shop is, the higher the cost of transporting products, which can increase the final price of water.

The following are the plus points:

- The demand for buying bottled water is increasing because the quality of tap water in many homes leaves much to be desired.

- Quick payback and high profitability if consumers like water.

- The possibility of expanding the range at any time, if there is enough space for the installation of additional equipment.

- The procedure for producing water is simple and does not require special skills if you hire a good process engineer.

Eventually

It is possible to open the production of drinking water if there is a good water source, funds for the purchase of an automated line and distribution channels so that the products are not stale in the warehouse. More complete information on this type of business can be obtained from the business plan for the production of drinking water, posted on our website.

Any foods and liquids must be of good quality so that a person is not threatened with serious poisoning and illness. The requirements for water are even tougher, because without it no life is possible. But there are few reserves of pure natural water that can be drunk without pre-treatment. Tap liquid has to be passed through a filter, settled or boiled. But, when thirsty, there is no time and desire for such procedures. It is easier to buy bottled water in a store or order it home through a delivery service. There is never enough drinking water, and demand is growing. This enables the entrepreneur to develop a business plan for the production of drinking water and offer his range on the market.

To understand what investments are needed to implement the idea, it is advisable to prepare a business plan for the production of drinking water with calculations. It can be presented as a clear example to banks or other partners who decide to help financially.

Summary

It is planned to launch the production of carbonated and non-carbonated drinking water without any additives. The main activity is aimed at the production of non-alcoholic beverages.

Raw material will come from a personal well. The deposit was found, the quality and composition of water were determined in the state laboratory. The well is located in a forested area. There is no opportunity to establish production directly at the source. Therefore, the water will be pumped into tanks and delivered to the production located in the suburbs.

Premises: 2-storey building with an adjacent territory. The area of the premises is 300 sq. m. On the 1st floor there will be a workshop and a warehouse, on the 2nd floor there will be rooms for staff and administration. The building needs repair and redevelopment, summing up communications.

Form of activity: LLC (limited liability company). Activity code No. 11.07 - "Production of soft drinks, various bottled drinking water."

Taxation - simplified (USN).

Service list

- Production of drinking water, carbonated and non-carbonated.

- Wholesale to grocery stores and supermarkets.

- Address delivery to customers on call.

Production mode

Production: daily from 09.00 to 19.00.

Address delivery service: from 08.00 to 20.00.

Preparation of documents

Based on the fact that the raw materials will be used from our own well, you need to draw up documents for this site. Having received permission and the right to work, we hand over water for research to the state laboratory. Expert opinion in hand. Water does not contain large impurities, which will reduce the number of purification steps. The worse the water, the more expensive the production will be and the more difficult it will be to compete with water with better taste.

- Permission from the administration to open a drinking water plant.

- Lease agreement for the premises in which the production of drinking water will be located.

- Conclusion of the SES on the possibility of opening a workshop in the selected area.

- The conclusion of the fire department on safety conditions.

- Quality certificates for equipment that will be used at the enterprise.

- Certificate of water quality that will be supplied to the consumer. Without this passport, shops will not take goods to their shelves.

- An agreement with the power supply company for the connection of a high-capacity line, because the production line is fully automated.

- Employees must have a health book and an employment contract.

Project estimate

Let's move on to an important part of the business plan - calculations. This will allow you to determine the costs that will arise during the preparation stage for the launch of the bottled water line. We will reflect the expense items in the table:

| Type of expenses | Amount of investments, thousand rubles |

| Collection of documentation and business registration (water analysis, well design, coordination with inspection departments, product licensing) | 250 |

| Equipment of the production area | – |

| Blow molding machine for plastic bottles from 0.5 to 10 liters | 800 |

| Molds for containers | 50 |

| Line for automatic bottling of water into containers (up to 3 thousand bottles per hour) | 900 |

| Apparatus for sticking labels on a bottle and a stamp with a production date | 300 |

| Bottle cap screwing device | 150 |

| Saturator (apparatus for the formation of gases in water) | 300 |

| Bottle Wrapping Machine in General PET Film for Shipping | 400 |

| Submersible pump for pumping water from a well into a tank | 100 |

| Accessories for underground water supply connecting the pump and the tank | 500 |

| Water tanks | 300 |

| Ozonator for disinfection and saturation of water with oxygen | 150 |

| Coarse and fine filters | 250 |

| Station for industrial water treatment | 2 500 |

| Total | 6 million 150 thousand |

This is the cost of equipping a well and a water production workshop with equipment. Additionally, funds will be required for cosmetic finishing, furnishing, and communications.

Investment information is preliminary. The cost of equipment, finishing materials, different services may differ, because the performers and suppliers have not yet been selected. But preliminary investments of more than 10 million rubles are needed to start the production of drinking water. Transportation costs for the movement of raw materials from the well to the plant, delivery of products to customers, funds for the operation of production until the first profit is not taken into account. Let's add 1.5 million rubles to these costs. The final estimate is 11.5 million rubles.

Personnel issue

The production needs employees who will work at the groundwater extraction site and at the plant. For the full operation of the complex you will need:

- Underground water extraction specialists - 2 people.

- Driver for transportation of raw materials and bottled water - 2 people.

- Equipment adjustment engineer - 2 people, shift work schedule.

- Operator for the water production line - 2 people. in shifts.

- Operator on the container blowing machine - 2 people. in shifts.

- Finished goods warehouse manager - 2 people. in shifts.

- Sales manager - 1 person, working mode 5/2

- Dispatcher for receiving individual applications - 2 people. in shifts.

- Production manager - 1 person.

- Accountant with the functions of a personnel officer - 1 person.

- Handymen - 4 people.

- Cleaner of production and service areas - 2 people.

Perhaps, as the plant develops, it will be necessary to expand the staff. Payroll costs are reflected in the table:

| Employee category | Quantity, pcs. units | S/P | TOTAL |

| Water extraction specialist | 2 | 15000 | 30000 |

| Driver | 2 | 18000 | 36000 |

| Engineer | 2 | 20000 | 40000 |

| Operator | 4 | 15000 | 60000 |

| Warehouse Manager | 2 | 10000 | 20000 |

| Manager | 1 | 20000 | 20000 |

| Dispatcher | 2 | 10000 | 20000 |

| production manager | 1 | 30000 | 30000 |

| Accountant | 1 | 25000 | 25000 |

| Handyman | 4 | 12000 | 48000 |

| Cleaning woman | 2 | 8000 | 16000 |

| FZP | 23 | – | 345000 |

| Contributions | – | – | 103500 |

| General expenses | 448500 |

The plant provides a shift work schedule for some employees. This is due to the daily work of production in order to quickly reach the required profitability of the enterprise.

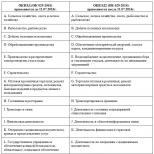

We plan the timing of preparations for the opening

So that the preparation process does not drag out, we will set a time frame for each stage and follow this plan:

It will take about 6 months for the shop to operate at full capacity. The dates may change due to unforeseen circumstances. It is desirable that water becomes available to the consumer in the summer season. At this time, the demand for bottled water increases due to the high air temperature and increased thirst. You can quickly make a profit and analyze the profitability of the business.

Range and prices for water

The production is young and has not yet found its client. Therefore, you should not open a line of a wide range of bottled water. The list of products and cost will be reflected in the table:

As the payback is reached, water for children and mineral water can be added to the assortment.

What will we get as a result

Let us calculate the possible profit that the production of water should bring to the entrepreneur. We will take as a basis the implementation of the entire range, provided that there will be a daily shipment of 2000 bottles of various volumes.

| Product type | Quantity, pcs. | Price per one. rub. | Revenue per day, rub. |

| Drinking water, non-carbonated, volume 0.5 l | 250 | 15 | 3750 |

| Drinking water, non-carbonated, volume 1 l | 250 | 20 | 5000 |

| Drinking water, non-carbonated, volume 1.5 l | 300 | 28 | 8400 |

| Drinking water, non-carbonated, volume 5 l | 250 | 80 | 20000 |

| Drinking water, non-carbonated, volume 10 l | 300 | 140 | 42000 |

| Drinking water, carbonated, volume 0.5 l | 100 | 18 | 1800 |

| Drinking water, carbonated, volume 1 l | 200 | 22 | 4400 |

| Drinking water, carbonated, volume 1.5 l | 200 | 32 | 6400 |

| Drinking water, non-carbonated, volume 2 l | 150 | 40 | 6000 |

| TOTAL | 97750 |

Provided that the daily revenue is 98,000 rubles and shipments are made at least 5 times a week, the monthly revenue is planned to be 1,960,000 rubles. Now you can calculate the profitability and net profit that will be received per month. Income and expenses will be reflected in the table:

At the initial stage, investments in the amount of 11.5 million rubles were made. The company will reach payback in 2.5 years. The term may change if the turnover for the month is higher than that taken as the basis for the calculation in the business plan.

Strengthening our position in the segment

There are many producers of drinking water on the market, so the struggle is going to be serious. You need to think over a strategy to consolidate your position in the market and attract an audience that is already buying bottled water. You will need the help of a specialist who knows the state of the niche and the position of other manufacturers. We will turn our attention to the production side in order to provide people with high-quality water.

At the initial stage, we focus on the delivery of water on an individual request, so that local residents learn about our products. For this:

- Together with the supplier, we will launch a promotion designed for a large volume of delivery. For example, every 3rd bottle is a gift, or with a one-time payment for 10 bottles of water, a 10% discount on the entire volume.

- Conduct a water tasting in a supermarket so that consumers evaluate the quality and submit an application.

- Send out electronic and written messages about cooperation with enterprises, offices on favorable terms.

- Offer services to kindergartens, schools, universities at a reduced price for a one-time application of at least 5 bottles.

- Design a website where you can post information about your production and favorable terms of cooperation for retail and wholesale customers.

Follow the pricing policy of competitors so as not to get out of the general system by too high the cost of drinking water.

Eventually

It is possible to earn solid capital in the production of drinking water if there is finance for this, a good source of groundwater and an area for a workshop. Huge investments are required, because the process of purification of raw materials requires only a high-quality automated line. Do not be afraid of competition. Consumers usually prefer water from local producers, believing that it is unprofitable for a businessman to deceive his countrymen. But you should be prepared for frequent SES checks for the quality and composition of products so that there is no threat to the health of consumers.