Technology of growing oyster mushrooms. Growing oyster mushrooms at home: technology. Requirements for the premises

2018-01-25 Igor Novitsky

Growing oyster mushrooms is a truly unique process, and all because for this purpose agro-industrial waste is needed, thanks to which it is possible to grow high-quality mushrooms rich in proteins, amino acids, minerals necessary to maintain the health and full functioning of the human body.

Another indisputable advantage of oyster mushrooms is their low calorie content and the complete absence of cholesterol, which is dangerous for our body. Since mushrooms contain a large amount of polysaccharides, they do not lose their shape with any type of cooking, which makes them look even more appetizing. Due to their unsurpassed qualities, in the old days these mushrooms were called "ishvin", which is translated from Old Russian as "valuable". Even our ancestors realized that this mushroom is beneficial for the body and began to use it for food.

You can quickly and relatively easily grow oyster mushrooms on sawdust and shavings, as well as on any type of wood. The easiest way is to grow mushrooms on stumps that remain after cutting down any tree species in the forest, on a personal plot, etc. However, in recent years, the cultivation of oyster mushrooms has been actively carried out on an industrial scale.

Oyster mushrooms grow quickly and are resistant to pests, which is why the cultivation of mushrooms in an industrial way is gaining momentum every year. These mushrooms, unlike the same champignons, are much easier to grow and they are less expensive in terms of resources, which won the hearts of farmers.

So, let's move on to the most important thing and find out how oyster mushrooms are grown under industrial conditions. It is divided into the following technological stages, consisting in:

So, let's move on to the most important thing and find out how oyster mushrooms are grown under industrial conditions. It is divided into the following technological stages, consisting in:

- Preparation of the substrate component.

- Inoculation of the substrate component.

- Sprouting block with substrate.

- Drive out the mushrooms.

- Harvest.

Substrate component preparation process

Growing oyster mushrooms primarily depends on the preparation of the substrate component. It must be of high quality, otherwise there will simply be no harvest. Industrial mushroom producers use cereals, corn cobs and stalks, non-coniferous sawdust, sunflower husks, grape vines or reed stalks as a substrate component.

In order to avoid mold in the substrate, it is treated at high temperatures before sowing, pasteurizing the material. In nature, along with oyster mushrooms, mold also grows, competing with it in development, making mushrooms weak and often unsuitable for food.

In order to avoid mold in the substrate, it is treated at high temperatures before sowing, pasteurizing the material. In nature, along with oyster mushrooms, mold also grows, competing with it in development, making mushrooms weak and often unsuitable for food.

In the industrial production of oyster mushrooms, sterilization of the substrate is not carried out, since it will not be possible to maintain complete sterility at all stages of cultivation. It can be provided only in the laboratory, and this is very costly and simply pointless.

Amateur mushroom pickers who grow oyster mushrooms on their own in the country or at home pasteurize the substrate, just like in production. To do this, polyethylene bags with a thirty-centimeter layer of substrate are taken, filled with boiling water, wrapped and aged for two to four hours. The pasteurization temperature should not be below fifty-five degrees and above sixty. After pasteurization, the substrate is left to ripen at a temperature of forty-eight to fifty degrees for seventy-two hours. After the time has elapsed, it is cooled to twenty-five degrees, and only after that the mycelium can be planted.

Substrate Component Inoculation Process

In a substrate cooled to twenty-five degrees, a mycelium is planted. The temperature regime should not exceed the declared one, since the mycelium may die. Before planting the mycelium, especially if it was stored in a refrigerator, it must be kept for twenty-four hours at room temperature. When planting mycelium in the substrate, complete sterility must be observed. Before planting the mycelium, the container in which it should be placed must be disinfected. Sterile gloves must be put on the hands, having previously treated them with a 1% solution of sodium hydrochlorate. It is necessary to introduce mycelium into the pasteurized substrate component in layers or evenly mixing the mycelium with the substrate.

The substrate component is placed in polyethylene bags or in other selected containers. Before placing the bags on the shelves, shake them a little and seal the neck with adhesive tape so that the substrate adheres well to the walls of the burlap. On the sides of the bags, it is necessary to make holes with a diameter of ten millimeters for perforation. Each bag carry up to fifteen kilos. After filling the bags with the substrate component with mycelium, it is necessary to place them in a humid, well-ventilated room for germination. In industrial conditions, such premises are prepared in advance so that future mushrooms feel “comfortable”

The substrate component is placed in polyethylene bags or in other selected containers. Before placing the bags on the shelves, shake them a little and seal the neck with adhesive tape so that the substrate adheres well to the walls of the burlap. On the sides of the bags, it is necessary to make holes with a diameter of ten millimeters for perforation. Each bag carry up to fifteen kilos. After filling the bags with the substrate component with mycelium, it is necessary to place them in a humid, well-ventilated room for germination. In industrial conditions, such premises are prepared in advance so that future mushrooms feel “comfortable”

The process of germination of blocks with a substrate component

This process is called incubation. It lasts from fourteen to eighteen days. During this time, the entire prepared block substrate sprouts with mycelium. For this period, light and ventilation are not of particular importance. The optimal microclimate is to maintain a temperature of twenty-four degrees and a humidity not higher than seventy-five percent and not lower than ninety. If the substrate temperature is higher than the room temperature, the walls will begin to condensate.

Such a problem is fraught with many troubles. A crust (stroma) can form on the mycelium, which will significantly reduce the yield of future mushrooms. It can also appear as a result of overheating of blocks with a substrate or in an excess of introduced mycelium.

Such a problem is fraught with many troubles. A crust (stroma) can form on the mycelium, which will significantly reduce the yield of future mushrooms. It can also appear as a result of overheating of blocks with a substrate or in an excess of introduced mycelium.

Violation of the microclimate can also lead to the appearance of mold, leading to the death of oyster mushrooms. It manifests itself in the appearance of orange, black and green spots on bags with mycelium. If this happens, the employees of the enterprise remove the affected bags, ventilate the room and level the microclimate to the required norm.

The process of forcing fruiting bodies

Oyster mushrooms can bear fruit, maybe in another room. But often the cultivation of mushrooms in an industrial way involves the entire process from sowing to harvesting in one room. For this purpose, experts simply change the temperature and humidity, following the growth of mycelium.

Three days after laying the bags with the substrate and mycelium into the room, the temperature is reduced to seven degrees and this mode is maintained for ninety-six hours. Such a temperature shake is done so that the oyster mushrooms begin to bear fruit. After the time has elapsed, the temperature is raised to fifteen degrees and kept stable until harvest.

Three days after laying the bags with the substrate and mycelium into the room, the temperature is reduced to seven degrees and this mode is maintained for ninety-six hours. Such a temperature shake is done so that the oyster mushrooms begin to bear fruit. After the time has elapsed, the temperature is raised to fifteen degrees and kept stable until harvest.

The optimal lighting for the normal growth of oyster mushrooms is eight thousand lux for twelve hours. To grow oyster mushrooms, it is imperative to comply with all of the above requirements. If there is a lack of light during the growth of mushrooms or if the level of carbon dioxide is exceeded, the mushrooms will have long and deformed legs, and in the worst case, they will simply stop growing.

Oyster mushroom has a wave principle of fruiting. If all the optimal conditions for the growth of oyster mushrooms are observed, then a couple of weeks after the bags with mycelium are transferred to the prepared room, the first wave growth will begin after three to four weeks. He will bring seventy percent of the harvest. In the next two to three weeks, the second wave of fruiting will pass and bring the remaining thirty.

Harvest process

Oyster mushrooms are cut from the very surface of the substrate component. You need to cut off all the mushrooms, leaving them is not recommended. During harvesting, watering the mushrooms is not necessary. This is done in order not to overmoisten the soil and not to stain the crop. Dirty mushrooms do not store well and quickly begin to deteriorate.

Cut oyster mushrooms are stacked in wooden boxes forty centimeters high. In boxes, the mass of mushrooms should not exceed fifteen kilograms. Store them at a temperature of two to four degrees. This mode allows you to save mushrooms for up to two months. If the temperature is higher, then the mushrooms will be stored for a maximum of a week.

Cut oyster mushrooms are stacked in wooden boxes forty centimeters high. In boxes, the mass of mushrooms should not exceed fifteen kilograms. Store them at a temperature of two to four degrees. This mode allows you to save mushrooms for up to two months. If the temperature is higher, then the mushrooms will be stored for a maximum of a week.

When the last crop is harvested, the substrate is removed, the room is washed and disinfected. Then there is preparation for the next cycle of fruiting. The whole process from inception to fruiting takes two to two and a half months.

Growing oyster mushrooms on a mini-farm in Tula

The oyster mushroom farm is located in Tula in the village of Arkhangelskoye. The farm has been operating for more than ten years, but is still the only one of its kind for growing oyster mushrooms in central Russia. Farmers have chosen this type of mushroom due to the fact that oyster mushrooms are very popular among the population.

After inoculation, the substrate blocks are placed in one large incubation chamber. Typically, the calculation of the load of such a chamber is based on the tonnage of the substrate, which ensures the loading of a certain area in the growing room in accordance with the loading schedule (1110; 1/8; 1/6; 1/4, etc. of the total tonnage of the hall).

The chamber is equipped with a supply and recirculation unit with air heating and cooling.

The ventilation system provides a constant distribution of the air mixture at the rate of 250 m 3 /ton of substrate. If there are blocks of different ages in the chamber (a gap of 4 or more days), then an average temperature regime is set, which depends on the ability of the substrate to warm up at the peak of the incubation temperature regime (the temperature delta inside the block and in the room should not exceed 10 0 С). Thus, if the substrate blocks are able to warm up to 31-32 0 С, then the temperature in the incubation room is set 21 0 С.

Maintains moderate humidity (65-75%) . CO 2 level - increased, can reach 4500-5000ppm.

If the humidity level is maintained by supplying a certain volume of fresh air, then oxygen contributes to good gas exchange and has a positive effect on the growth of mycelium in the thickness of the substrate. On some strains under such incubation conditions, the appearance of signal primordia is possible.

The growing system is multi-chamber single-zone.

After inoculation or transport, substrate blocks are placed in a pre-washed and disinfected chamber. Particular attention should be paid to the prevention of the air distribution system (clean from dirt, spores, mold, treat with disinfectants).

Blocks must be brought into a warm room. room temperature should contribute to the creation of an optimal temperature regime in the block for the development of mycelium (24-28 0 С). Under such conditions, the mycelium covers the substrate in 5 days, which will provide it with superiority with competing microorganisms and molds. The air temperature in the room must be stable throughout the entire incubation period. (for example, 21 0 С).

Requirements for the parameters of substrate blocks:

- Nitrogen: 0.7-0.8;

- Humidity: 69-73%;

- Stuffing density: 0.4-0.6 kg/liter;

- CIN ratio: 55-60;

- The delta of temperatures (the center of the block - the room) at the peak of heating of the blocks will be 8-10 0 С;

- Relative humidity within 65-75%;

- The level of CO 2 is elevated (can reach from 2500-5000ppm).

Fruiting of the first wave.

The cultivation system is single-chamber, two-zone.

After incubation, the blocks are transferred to the fruiting chamber, where the average climatic parameters for blocks of different ages are maintained: CO 2 level, humidity and air temperature.

The transfer of blocks, the decrease in CO 2 level and temperature initiates the appearance of primordia. Rest between waves takes place under the same conditions, so there is no way to control the timing of fruiting. A mandatory requirement is to maintain stable microclimate parameters without fluctuations.

Approximate schedule for oyster mushroom cultivation.

| Day | Development phase | Terms | Notes |

| 1 | Incubation |

T air - 22 0 С; CO2 - up to 4000ppm |

During the period of maximum heating, the temperature of the substrate reaches 32 0 С |

| 16 | fruit formation | ||

| 17-20 | Fruiting |

T air - 14-15 0 С; CO2 - 850-950ppm |

Maintain stable air parameters. In unstable conditions, fruiting stretches for longer periods. The cultivation cycle can be 48-60 days |

| 17-20 | Primordia massively | ||

| 24-28 | Collecting 1 wave | ||

| 29-39 | rest | ||

| 35-40 | Primordia massively | ||

| 42-48 | Gathering 2 waves |

Growing system multi-chamber single-zone.

Substrate blocks are installed in place immediately after inoculation or delivery (if purchased substrate).

Mycelium in the first day after application only begins to wake up and is resistant to shaking during transportation. The substrate does not have time to warm up yet, there is no danger of damage to the mycelium by high temperature. Oxygen consumption during this period is reduced to a minimum. Blocks, even if they are wrinkled during transportation, are easy to correct giving them the desired shape.

Under such conditions, it is possible to provide qualitative overgrowth of the substrate and the simultaneity of the appearance of primordia, which contributes to a friendly wave of fruiting.

Fruit formation is initiated by lowering the air temperature and lowering the CO 2 concentration.

The smooth cooling process usually lasts 2-3 days.

Decrease in substrate temperature up to 16-18 0 С is produced by supplying fresh air according to the cooling options, according to the table.

Rapid cooling implies a large volume of fresh air, a decrease in CO 2 levels, fluctuations in air humidity, which leads to inhibition of the formation of primorie for 34 days.

Moderate and mild cooling is easy to carry out in the cold season, using mainly recirculation air. With an increased level of CO 2 and high humidity, primordia are formed quickly and in large numbers.

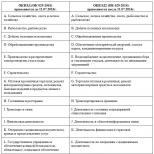

Variants of the "Cooling" phase

| Options | T incoming air CO | CO 2 level, ppm |

RH, % |

| Rapid cooling (lots of fresh air) |

13-18 |

600-700 |

85-90 |

| Moderate cooling (30-40% fresh air of the total volume) |

14-16 | 900-1000 | 86-90 |

| Light cooling (mostly recirculates with 10-15% fresh air) |

14-16 | 1200-1500 | 90-95 |

When choosing a cooling option, consider the following factors:

- CO 2 level during incubation: from 10 to 14 days, the level of CO 2 decreases to 2500-200 ppm;

- strain characteristics.

In the cultivation of today's strains, there are significant differences in the cooling phase.

For Chinese- moderate or mild cooling is used, with time a lot of mushrooms are formed, which from the very beginning look fleshy. An increased level of CO 2 contributes to the formation of a large number of fungi in the joint, but will not affect the size and density of the fungal body.

NK-35- apply moderate or rapid cooling. A high level of CO 2 (especially if the incubation was carried out without fresh air) promotes the emergence of intergrowths with a large number of fungi, which later develop into small and thin-walled with thin legs. The lower the CO 2 level, the fewer mushrooms in the drusen and the larger the mushrooms will be.

The first wave of fruiting.

The mushroom grows due to evaporation, the conditions for which are provided by the climatic parameters in the hall. When creating stable microclimate conditions in the room (there are no sharp fluctuations in temperature and humidity), a temperature balance is always established in the mushroom blocks, which ensures evaporation even at high ambient humidity.

The temperature in the center of the block is always higher than the temperature on the surface of the block, which is always higher than the temperature in the room (T 3 > T 2 > T 1). This energy reserve makes it possible to grow mushrooms at an air humidity of 90-95%, which ensures a high yield of the crop and leaves a potential reserve of substrate moisture content for subsequent fruiting waves.

After the formation of primordia, the CO2 level decreases to 800-900ppm. The optimum air temperature is 13-15 0 С.

At a higher temperature, fruiting will be faster, but the quality of the fungus is worse.

The first wave requires a lot of fresh air to keep CO2 levels below 1000ppm. If the capacity of the equipment does not allow preparing the required volume of air, the mushroom loses its quality, the wave of fruiting is noticeably delayed and part of the crop dies.

Rest between waves.

After the end of the first wave of fruiting:

- the temperature in the chamber is raised to 18-20 0 C;

- humidity up to 90-95%;

- CO 2 level is moderate 1500-2000 ppm.

Fruiting of the second wave.

After the formation of the first primordia:

- Air temperature up to 15-16 0 С;

- humidity up to 90-93%;

- CO 2 level up to 900-1000 ppm.

If during the fruiting of the first wave the microclimate conditions were unstable, then a smooth transition to the second wave without a rest phase is possible. In such cases, the fruiting of the second wave will be less friendly and longer.

The second wave of fruiting.

Since the activity of the substrate on the second wave is weaker, it is easier to maintain the parameters more stable. If it was not possible to realize the potential of the harvest in the first wave, then the second wave can produce a harvest at the level of the first.

The duration of the fruiting cycle is regulated by the mushroom grower himself based on economic aspects.

Mushroom cultivation is rightly considered one of the most profitable types of agricultural business. The organization of such a process usually does not require significant costs, and a short production cycle and high demand for products allow the entrepreneur to make a decent profit. All this fully applies to the cultivation of oyster mushrooms - an unpretentious and accessible mushroom for artificial breeding.

Considering where to start growing oyster mushrooms at home from scratch, first of all, attention should be paid to a theoretical study of the issue. In order for the harvest to be of high quality, you need to know what conditions are preferable for mushrooms, how to apply fertilizers, how to choose the right mycelium. As for the practical part, the cultivation of any kind of plants is accompanied not only by logic, but also by intuition based on experience: without this knowledge, it is difficult to create a successful production.

Properties and features of oyster mushrooms

The simplicity and accessibility of the technology for growing oyster mushrooms at home are of constant interest to entrepreneurs who want to open a business with little investment. As for nutritional value, according to these indicators, oyster mushroom occupies one of the first places among mushrooms, representing an affordable source of vitamins and microelements, and its culinary qualities make it possible to prepare many dishes by simple processing.One hundred grams of oyster mushrooms contain 3.3 g of protein, 0.4 g of fat and 4.15 g of carbohydrates with an energy value of 43-44 kcal. Studies show the presence of vitamins B1, B2, D, PP, ascorbic acid and amino acids in mushrooms. In addition, the indicated quantity of the product includes:

- Zinc, useful for immunity (6% of the daily requirement of an adult);

- Potassium necessary for the work of the heart and kidneys (9% of the daily requirement);

- Iron affecting the process of hematopoiesis (8% of the daily requirement);

- Phosphorus and copper (12% of the daily requirement).

The basis of the mushroom is low-calorie fiber, due to which the microflora of the digestive tract is normalized, and nutrition becomes more balanced.

Is it profitable to grow oyster mushrooms in your own basement, in the country or in a specially rented room? To answer this question, it should be taken into account that 8–10 crops can be obtained per year, and a square meter of usable area in one cycle brings an entrepreneur up to 30 kilograms of products.

Mushroom cultivation technology

In artificial breeding, extensive and intensive technologies for growing oyster mushrooms at home are used. The first involves planting mushrooms in conditions as close to natural as possible, and the second involves the creation of a special nutrient medium in specially equipped rooms. The advantages of the extensive method are simplicity and minimal investment, which is applicable when . With the intensive method, a large crop can be harvested in a short time, destined for sale.

Growing methods

on stumps

In extensive methods, spores or mycelium of fungi are placed on previously prepared soil, which is used as sawdust, wood chips, shavings or other wood waste mixed with peat. The simplest is the cultivation of oyster mushrooms on stumps left after harvesting deciduous forests or cutting down fruit trees on your own plot.

With this method of sowing, grain mycelium is applied to clean sections of stumps, into cuts or pre-drilled holes up to 4 cm deep and up to 5 cm in diameter. Then the planting site is protected with sawdust or a wooden cork, the stumps themselves are covered with a film and sprinkled with earth. Harvest should be expected in 3-4 months.

Growing oyster mushrooms in the basement

On sawdust

The method of growing oyster mushrooms on sawdust or shavings is as follows: previously dug trenches up to 20 cm deep are filled with a substrate, and then treated with spores in suspension (or placed in shallow holes of grain mycelium). The landing site is sprinkled with the remaining substrate, covered with a film, and pressed down with earth from above. After two or three months, mushrooms can be harvested.

in bags

Intensive methods involve growing oyster mushrooms at home in bags filled with a mixture of various agricultural waste (straw, husks, corn) and set in a room with specified levels of temperature and humidity. Such bags are otherwise called mushroom blocks.

Room preparation

As a room for growing oyster mushrooms at home, at the initial stage, you can use a greenhouse, basement or other outbuilding, however, larger-scale production requires renting additional space.

The workshop should be divided into several sections isolated from each other:

- Substrate preparation area equipped with a grinder;

- Pasteurization and block preparation area;

- Dark room for incubation with a temperature of 18–22°C;

- A cool room for fruiting with a temperature of 12–15 ° C and a humidity of 80–90%, periodically artificially lit.

To grow oyster mushrooms at home, indoors, you need to provide access to electricity and water supply, as well as arrange heating (electric, gas or wood) and ventilation. The required air humidity is controlled by a hygrometer and is provided both by irrigating the mushroom blocks and by using a humidifier.

Unfortunately, mold grows well in such humid conditions. It is imperative to deal with it - by periodically warming up the room, treating surfaces with antiseptic compounds and regular cleaning. Pests are destroyed by insecticides and smoke bombs a week before the laying of mushroom blocks, and immediately before placing the blocks, the incubation and fruiting zones are disinfected with bleach and carefully cleaned.

Necessary equipment

With small production volumes when growing oyster mushrooms at home from scratch, the bags can be placed directly on the floor. However, in order to save space, it is advisable to prepare lattice racks or weld a frame for hanging mushroom blocks on top of each other: with multi-tiered placement, 6–8 bags are placed on one square meter.

Other equipment for growing oyster mushrooms is:

- heater or stove;

- Pasteurization tank or steam generator;

- Straw crusher;

- Fans and lighting lamps;

- Bags, pitchforks, containers for mushrooms, twine and other equipment.

Expansion of production requires the inclusion of an air conditioning and humidification unit, drip irrigation system and other equipment in this list, which you can consider purchasing after the business begins to generate a stable income.

Substrate preparation

Various wastes can be used as a substrate for growing oyster mushrooms: wheat or barley straw, hardwood shavings, sunflower husks, corn stalks, sawdust. The maximum yield is achieved precisely when using straw, which must be clean, without impurities and traces of infection.

The straw is crushed to a fraction of 2–5 cm using a crusher, after which various biological activators are added. When used as directed, these additives speed up the breeding cycle and increase yields by 25-30%.

Sterile technology for growing oyster mushrooms in bags involves the treatment of straw with hot steam or water. In the first case, you can not do without a steam generator, and the second allows you to use a large capacity.

In this case, you should:

- Tamp the straw into a 150-200 liter tank or place it there in a linen bag under the load (to prevent floating);

- Soak for 1-2 hours;

- Heat water to 70°C and keep the substrate at this temperature for three to four hours;

- Remove the straw and allow excess water to drain - the moisture content of the material should not exceed 70–75%;

- When the substrate has cooled, you can start planting.

For beginners, growing oyster mushrooms at home step by step also includes sterilizing plastic or polypropylene bags with a chlorine solution, hot water, or a quartz lamp. It is assumed that as a result of these operations, all pathogenic microflora will be destroyed, which will allow the mycelium to develop without the risk of infection.

The bags are filled with about three-quarters of the finished substrate mixed with mycelium. The weight of such a mushroom block with dimensions of 40x70 cm will be 12–14 kg, and 2–3 buckets of dry material are required to fill it.

Mycelium sowing

In advance, you should buy spores of oyster mushrooms or mycelium in bags. The second option is preferable: there are dozens of varieties with different yields, tastes and appearances to choose from - oyster mushroom, oyster, pink, lemon, steppe or Florida. The shelf life of seed in a refrigerator at a temperature of +2-3°C is several months, which allows you to create the necessary stocks for production.

Ready-made kits for growing champignons and oyster mushrooms at home are also on sale: in any case, before choosing an option, you should weigh the associated costs and evaluate the prospects: the independent process of making the substrate and sowing is highly labor-intensive, but leads to significant savings.

Mycelium is purchased at the rate of 4-5% by weight of the substrate, which is equivalent to 450-550 grams per bag. The day before planting, the packaging should be removed from the refrigerator and kept at room temperature, and then thoroughly kneaded under sterile conditions using gloves.

In accordance with the technology of growing oyster mushrooms at home, when filling the bag, each layer of the substrate 10–12 cm thick is lightly rammed and sprinkled with a thin layer of mycelium. After filling, the bags are tied and placed in an incubation zone with a temperature of 18–22°C and a humidity of 75–90%, leaving a small distance between them to avoid overheating.

Growing process

During incubation, the temperature inside the bags must be monitored daily: due to ongoing biochemical processes, there is a continuous release of heat. If the value of 28–30 ° C is exceeded, the mycelium may die: in order to avoid this, it is recommended to immediately lower the temperature in the room or pour cold boiled water on the mushroom blocks. After 3–4 days, checkerboard cuts 4–6 cm long are made on the bag on both sides every 12–15 cm. The cuts should be made so that the mushrooms do not interfere with each other during growth.

When growing oyster mushrooms in bags, the incubation period lasts three to four weeks. During this time, the mycelium filaments grow and braid the substrate, turning the contents of the bag into a homogeneous white mass. Soon, small clusters of fruiting bodies appear in the slots, indicating that it is time to transfer the bag to the fruiting zone.

In the fruiting zone, the bag is placed at a distance of 12–20 cm from each other. In the room itself, you need to maintain a temperature in the range of 12–18 ° C and a humidity of about 85%. When growing oyster mushrooms in the basement, dim lighting will require fluorescent lamps (one per 5–7 m² of room area), which are turned on daily for 8–10 hours.

Water the mushroom blocks with water at room temperature using humidifiers or a drip irrigation system. However, oyster mushrooms do not tolerate excess moisture well, so the room must be well ventilated so that the mushroom caps have time to dry out between waterings.

Harvesting

Fruiting begins 8–9 days after the appearance of the first fruiting bodies and continues for a month and a half. When the mushroom caps reach a size of 7-10 cm, the bunches can be plucked. When growing oyster mushrooms at home for sale, it is recommended to twist the fruiting bodies out of the bag: using a knife can lead to infection of the mycelium and subsequent decay.

The remains of the substrate and straw are removed from the mushrooms, after which they are carefully placed in boxes. Oyster mushrooms can be stored at room temperature for 1-2 days, and in the refrigerator for up to a week.

The mushroom blocks themselves are returned to the dark incubation chamber. After some time, fruiting bodies reappear on them, representing the second wave of the harvest. After the third wave, the bag is replaced with a new one, and the spent substrate is disposed of or used as fertilizer.

In general, for beginners, growing oyster mushrooms at home in bags allows you to collect a total of up to 3.5 kg of mushrooms from one block, and when using bioactivators - up to 4.5 kg. Given the short shelf life, the implementation should be taken care of in advance to avoid product spoilage.

Sales of products

All production processes should be preceded by studying the market for oyster mushrooms and establishing contacts with wholesale buyers. During the sale, the products are packed in plastic trays with the help of cling film and supplied with a label with the manufacturer's data and production date. You can sell mushrooms:

- By direct sale in agricultural markets, where an advertising outlet should be equipped;

- To restaurants, cafes or other catering establishments - you can start with free samples and convince the owners of the quality of the product;

- To retail stores, supermarkets and retail chains - this will require accompanying documents and certificates;

- Wholesale buyers.

The mushroom business also offers some opportunities for generating additional income: this is the cultivation of oyster mushroom mycelium at home for sale and the sale of spent mushroom blocks as fertilizer or livestock feed.

Business registration

For beginners, growing mushrooms at home for the purpose of personal consumption or sale to friends and acquaintances does not require official paperwork. However, the mass sale of oyster mushrooms is impossible without registering the activity and obtaining an expert opinion. The easiest way is to use an individual entrepreneur and choose the ESHN as a taxation system with a rate of 6% of the profit.

As for the sale of consignments of goods to shops and restaurants, here you should submit product samples to the sanitary control authorities in advance and receive:

- Declaration of conformity with the requirements of the standard;

- Phytosanitary certificate;

- Protocol of radiological research.

Financial investments and income

When choosing, you should at least approximately estimate the associated costs. In the case of growing oyster mushrooms, this depends on the availability of suitable premises, a heating system, access to raw materials for preparing the substrate, and the cost of energy.

Suppose that it is planned to create a medium-capacity production facility, consisting of a thousand mushroom blocks placed in two tiers in a rented room with an area of 200–250 m². Based on the fact that the production cycle for oyster mushrooms is two months, we get:

Costs in the production cycle

Based on the fact that up to 4.5 kg of oyster mushrooms can be grown on each block, 4–4.5 tons of crop can be obtained from the specified thousand bags. The average wholesale price for mushrooms today is 120-150 rubles per kilogram: this means that with full implementation, growing oyster mushrooms at home will bring 480-675 thousand rubles of income (142-337 thousand rubles of net profit), and organizing the sale of bags with used substrate to farmers as fertilizer or feed for livestock - another 5,000–6,000 rubles. In the next cycles, the profit will be even greater, since the necessary equipment has already been purchased.

Considering, it must be borne in mind that growing oyster mushrooms is characterized by certain advantages and disadvantages.

The benefits include the following factors:

- Mushrooms can be grown in a heated room all year round;

- Duration of the production cycle - no more than two months;

- Production can be made waste-free by selling used compost;

- Starting a business does not require large investments;

- You can grow mushrooms not only in the countryside, but also in the city;

- The business scales easily - one person can start with 200-300 mushroom blocks, and later hire staff and expand production.

The main disadvantage of the oyster mushroom growing business is the difficulty in selling large batches of products. It is necessary to pay great attention to the organization of sales in order to be able to sell several tons of mushrooms every two months. However, this can be avoided if mushroom blocks are sown not simultaneously, but at some interval - for example, no more than 20% of the total amount per week: in this case, production will turn from cyclic to continuous.

conclusions

When entrepreneurs look at agriculture-related production, dozens of businesses come into view. However, not all of them are characterized by the same level of profitability as the cultivation of oyster mushrooms: investments pay off almost with the first harvest.

As the technological process is organized in this business, additional prospects arise. Why not simultaneously with the cultivation of oyster mushrooms do something: for example, the sale of packaged mycelium or the manufacture of "mushroom stumps" for summer residents? As for the professional approach, it involves the purchase of a special processing line: canned and pickled mushrooms are in great demand and always find their buyer. Thus, a business started in your own basement in the future can turn into a large enterprise that brings a considerable income to the owner.

Growing mushrooms at home due to various factors is gaining unprecedented popularity. The leader among mushrooms grown at home is oyster mushrooms. This is not surprising, since it is the simplicity of technology, productivity and picky oyster mushrooms that makes them accessible to everyone. Following the recommendations and instructions, everyone can easily, using only improvised means and materials, harvest up to 3 kg of crop from each kilogram of the original mycelium. The symbiosis of the right room, the quality of the mycelium and the substrate is the key to the successful cultivation of oyster mushrooms at home.

Where to grow oyster mushrooms, the choice of premises

Growing oyster mushrooms at home, of course, should begin with solving a banal, but very important issue - choosing a location for mushrooms. When choosing, it should be borne in mind that in their natural habitat, almost all mushrooms, and oyster mushrooms in particular, grow most actively in places with good air exchange. Moreover, the humidity of places of growth, as a rule, exceeds the boundary of 50%.

Thus, the cultivation of mushrooms at home should be organized in premises that are able to recreate the natural environment. Such a room can be a greenhouse, a barn or a basement - this type of placement is the most popular, but in real conditions the choice will be individual and will depend only on the compliance of the room with the following requirements:

Thus, the cultivation of mushrooms at home should be organized in premises that are able to recreate the natural environment. Such a room can be a greenhouse, a barn or a basement - this type of placement is the most popular, but in real conditions the choice will be individual and will depend only on the compliance of the room with the following requirements:

- The humidity level of the room should be in the range from 70 to 90%;

- During the first three weeks, the bags of mycelium should be hidden from sunlight;

- After the appearance of the first fruit buds, bags with oyster mushrooms should receive artificial or daylight for at least 8 hours daily;

- The air temperature in the room should not be lower than 20 degrees, but not higher than 30;

- Throughout the entire period, the technology for growing oyster mushrooms at home implies the presence of good ventilation.

Important! The chosen premises are the basis and guarantee of productivity. The approach to solving this issue should be extremely serious, since non-compliance with any of the requirements presented can not only reduce the speed of growing a mushroom crop, but even completely eliminate it.

How to grow oyster mushrooms, preparation and processing of the substrate

Before you start growing mushrooms, you should understand how to grow oyster mushrooms and what the final result depends on. One of the fundamental points is the preparation and processing of the substrate, which is essentially a nutrient soil for growing oyster mushrooms. As with other stages, any mistake during the preparation stages can affect the yield, so it is recommended to follow simple rules and tips.

Mycelium is sold by many specialized stores and even individual companies that are directly involved in the cultivation of oyster mushrooms. It is the purchase from such manufacturers that is most desirable for a novice mushroom picker. In accordance with the requirements and technological features on a mass scale, the mycelium, as a rule, is not used for more than a year, but during this period it has not been fully developed, that is, it gives a significant yield. Such a mycelium has already been developed and is bearing fruit, and its cost is significantly lower than a new mycelium.

The volume of purchased mycelium should be determined depending on the desired yield - with good care at home, it is possible to get up to 3 kg of oyster mushrooms from each kilogram of mycelium. Keep in mind that oyster mushroom growing bags can produce up to three crops in a short period. It is rather difficult to base the choice of mycelium when purchasing on any indicators due to the lack of many obvious evaluation factors, which is why it is important not only to pay attention to the size of the mycelium, its vastness, but also to make a choice in favor of a trusted supplier-seller.

The volume of purchased mycelium should be determined depending on the desired yield - with good care at home, it is possible to get up to 3 kg of oyster mushrooms from each kilogram of mycelium. Keep in mind that oyster mushroom growing bags can produce up to three crops in a short period. It is rather difficult to base the choice of mycelium when purchasing on any indicators due to the lack of many obvious evaluation factors, which is why it is important not only to pay attention to the size of the mycelium, its vastness, but also to make a choice in favor of a trusted supplier-seller.

How to make your own substrate

The modern market is replete with a variety of substrates for growing certain plants, mushrooms. However, some mushroom pickers invariably opt for a substrate made with their own hands. Such a basis, of course, better takes into account the individual characteristics of the climate, care and conditions of detention, but it should be understood that the effectiveness of its use depends on the correct component composition, which, in turn, requires skills and knowledge.

The modern market is replete with a variety of substrates for growing certain plants, mushrooms. However, some mushroom pickers invariably opt for a substrate made with their own hands. Such a basis, of course, better takes into account the individual characteristics of the climate, care and conditions of detention, but it should be understood that the effectiveness of its use depends on the correct component composition, which, in turn, requires skills and knowledge.

Like vegetable soil, substrates for growing oyster mushrooms must contain a quality base and mineral composition. It is imperative that the base chosen - sawdust, husks, straw, etc. - be clean and pre-treated. It is highly recommended to avoid the use of chemically treated bases - it is worth remembering that oyster mushrooms are grown for consumption, so environmental friendliness and safety should come first.

Self-creation of the substrate is a fairly simple process, consisting of only three stages:

- Disinfection of the selected base by thermal and/or chemical treatment;

- Grinding the substrate to fractions no larger than 4-5 cm and repeated heat treatment for two hours;

- Spin.

Did you know?In addition to being eaten, oyster mushrooms have been used in traditional and folk medicine. So, in the folk recipes of the eastern countries, oyster mushroom is almost an integral part and is positioned as a panacea for many diseases.

Substrate preparation

Substrate preparation for growing oyster mushrooms begins with a banal, but extremely important choice of raw material base. The best germination and yield results are achieved in a substrate of wheat or barley straw, sunflower husks, crushed corn cobs and corn stalks, and buckwheat husks.

Substrate preparation for growing oyster mushrooms begins with a banal, but extremely important choice of raw material base. The best germination and yield results are achieved in a substrate of wheat or barley straw, sunflower husks, crushed corn cobs and corn stalks, and buckwheat husks.

Important! In practice, there is often a substrate based on sawdust or shavings of various types of wood, however, growing oyster mushrooms at home on a similar basisfor newbies– rather complex process, requiring, moreover, a more painstaking approach.

Already at the first stages of substrate preparation, it is strongly recommended to fully check the selected raw materials for cleanliness and the absence of mold. The next stage is the grinding of the raw material base into small fractions with a total size of no more than 5 cm.

To completely exclude contamination of the substrate with all kinds of harmful organisms, which is certainly unacceptable in the context of further consumption of grown oyster mushrooms for food, it is strongly recommended to subject it to heat treatment. Moreover, this procedure will also increase the moisture content of the raw material to the required level.

The processing process consists of several steps:

- Placement of cleaned and crushed raw materials in large volumes of metal utensils;

- Filling the substrate with a large amount of water (in a ratio of at least 1: 2);

- Boiling the substrate for 2-2.5 hours until the feedstock is completely softened;

- Draining the remaining water and cooling the substrate to a temperature of 30 ° C and its complete extraction.

Important! Waterlogging the original base, despite the dependence of oyster mushrooms on moisture, will certainly make the resulting substrate unsuitable for growing mushrooms at home. So, when compressing raw materials in the hand, only a small amount of drops is acceptable.

The process of forming mushroom blocks

Mushroom blocks are a kind of beds in which oyster mushrooms are grown. As a rule, a plastic bag is chosen as the "capacity" for the block. It should be noted that the bag must be disinfected or heat treated without fail. An effective treatment method is washing with a bleach solution. The optimal volume of the bag should be at least 5 kg.

After disinfection of the used substrate and container for it, the formation of mushroom blocks begins - layer-by-layer filling of the bag with the substrate and mycelium. Based on the recommendations of experienced mushroom pickers, there should be about 0.5 cm of mycelium for each 5-6 cm layer of substrate. It should be noted that the first and last layer in the bag must necessarily be a substrate.

At the end of filling the mushroom block, the bag is tightly tied at the neck. The final stage - perforation of blocks - consists in cutting small holes at a distance of 10 cm from each other. And it is best to do them in a checkerboard pattern.

How to properly care for oyster mushrooms

As a rule, it is not difficult to grow oyster mushroom mycelium at home - it is enough to create the proper climatic conditions and properly care for the mycelium during the ripening period, following the recommendations.

Maintaining climatic conditions, the incubation period of oyster mushroom ripening

Starting from the first days of growing mushrooms, you need to decide at what temperature mushrooms grow in the created conditions - the temperature should be constant (within 20 - 30 ° C) and not change by more than 1-2 degrees. Exceeding the upper temperature limit will certainly cause heat shock in the oyster mushroom mycelium and kill future mushroom shoots. Lowering the temperature is also detrimental.

Starting from the first days of growing mushrooms, you need to decide at what temperature mushrooms grow in the created conditions - the temperature should be constant (within 20 - 30 ° C) and not change by more than 1-2 degrees. Exceeding the upper temperature limit will certainly cause heat shock in the oyster mushroom mycelium and kill future mushroom shoots. Lowering the temperature is also detrimental.

Along with the temperature regime, growing mushrooms at home should be accompanied by a constant level of humidity. Fortunately, even novice mushroom pickers with no experience in growing oyster mushrooms have access to automatic systems for maintaining moisture through irrigation. The incubation period of maturation under optimal conditions, as a rule, takes about 20-25 days.

Did you know? The color of the oyster mushroom cap depends on the growing conditions created. So, the selected and constantly maintained temperature is about 20°C will allow you to get a light hat, and 28-30°C - dark. However, this does not affect the taste in any way.

How to care for mushrooms during the growth period

Caring for mushrooms, despite the seeming complexity, is quite simple and does not require special skills and means. The main requirement is to maintain the conditions of detention. During the incubation period, the room should not be ventilated, since the emitted carbon dioxide autonomously creates the most favorable conditions and slightly increases the level of moisture.

Caring for mushrooms, despite the seeming complexity, is quite simple and does not require special skills and means. The main requirement is to maintain the conditions of detention. During the incubation period, the room should not be ventilated, since the emitted carbon dioxide autonomously creates the most favorable conditions and slightly increases the level of moisture.

Today I would like to talk about how to grow oyster mushrooms. Everyone knows perfectly well that oyster mushrooms and champignons are mushrooms that we buy in supermarkets, because they are sold fresh. Why not try growing them yourself? You don't have to be a mushroom grower to do this. It will be enough to follow a certain sequence of actions and you will succeed.

So, if you are seriously considering growing oyster mushrooms, then you need to purchase mushroom mycelium. Fortunately, now there should not be any problems with this, since you can also make a purchase on the Internet, and there are plenty of companies that grow mushrooms, sell them and sell everything that is necessary for growing. If you are a beginner mushroom grower, then 1 kg of mycelium will be enough, let's say for an experiment. Perhaps something will not work, not like it, why overpay? Mycelium should be stored at a temperature of + 2-4 ° C, for which a refrigerator is quite suitable. Let's start with the preparation of the substrate.

Preparation of the substrate for oyster mushrooms?

To prepare the substrate, you can use various components (raw materials), namely: corn cobs, barley or wheat straw, buckwheat husks, sunflower. So, for example, when using straw, it must first be crushed so that the substrate is as dense as possible, because in nature oyster mushrooms grow on trees. Naturally, the material for the substrate must be clean, there should not be any traces of mold. About 10 kg will be enough.

The probability of contamination of the substrate with various harmful organisms can be reduced to almost zero by first subjecting it to heat treatment. The substrate is poured into a container of sufficient volume, completely filled with water and boiled for about 2 hours. After this treatment, drain the water and let the substrate cool down to 25-28 ° C. Speaking of humidity: the substrate should be moist, but not so much that water flows from it.

We form blocks from the substrate

The next step in the cultivation of oyster mushrooms is the formation of blocks, since mushrooms are grown with their help. The blocks are usually plastic bags stuffed with substrate. We divide our 10 kg in half, i.e. 5 kg for two packages. Again, do not forget about disinfection - we place the bags for a couple of hours in a bleach solution (1-2%). Next, we form packages - our future mycelium: we fill them with layers of substrate and mycelium. The substrate layer is 5-6 cm, mycelium is 0.5 cm on top, and so on until we fill the bag. The top layer is the substrate. After filling, we tie the bag and make holes 1-2 cm long like a chessboard after 10-15 cm.

Incubation period - oyster mushroom ripening

Once the packages have been prepared, they should be placed in the proper conditions. The incubation period is about 2-3 weeks. Indoors, it is necessary to maintain the temperature in the region of + 18-22 ° С. In addition, you need to provide ventilation (several times throughout the day). It is necessary to take measures to combat the flies. Adhesive tapes usually do a good job of this. During the first few days, the substrate will heat up. The main thing is to monitor the temperature in the bags: it should not be higher than +30 °C. Otherwise, the mycelium will simply disappear. To lower the temperature, you can use the same fan, because we are not talking about growing oyster mushrooms on an industrial scale. During this period, lighting is not necessary. After 10-12 days, the mycelium will grow completely throughout the substrate, which will look like a homogeneous mass.

Fruiting oyster mushroom

The next stage is fruiting, which we all have been looking forward to. If you have reached this process, then you can draw conclusions about the correctness of the work done. However, fruiting is not yet harvesting, so the following series of actions must be performed:

We reduce the temperature in the room to + 10-15 ° С;

unlike the incubation period, lighting for 8-10 hours using fluorescent lamps will now be required;

increase air humidity to 90-95%;

the room should be ventilated about 4 times a day.

How to grow oyster mushrooms?

Many may wonder - how to maintain the required humidity? To do this, you can spray both the floor and the walls with water, and water should not get on the substrate itself. If all conditions are met, then in the near future it will be possible to observe the appearance of small fungi, although it is still difficult to call it mushrooms. The fruiting period is about two weeks. Since in recent days the caps have increased significantly in size, this period is considered optimal for harvesting. It is worth noting that mushrooms need to be twisted out of the substrate, and not cut off, as many are used to. This also applies to picking mushrooms in the forest. The fact is that when cutting the mushroom, harmful organisms penetrate through the remaining leg, which damage the mycelium.

After you collect the first crop of oyster mushrooms, the room is well ventilated and then we are waiting for the second crop. Time is about two weeks. As for the subsequent conditions for growing oyster mushrooms, they remain the same as previously described. Up to 4 crops can be harvested from such “mushroom mushrooms”, with the first two being the most productive. After the fourth harvest, the contents of the bags will have to be replaced, unless of course you want to continue growing oyster mushrooms. As can be judged from the material described above, growing oyster mushrooms is not particularly difficult. In fact, mushroom growing is quite an exciting activity, because it's nice to see mushrooms grown by one's own hands on your table.