What do you need to open a sewing production. Open a sewing production. Interesting ideas for your own business

The modern market for clothing and textiles is overflowing with goods from China and Turkey. And, as a rule, the quality of such products corresponds to its low price: often the size range differs from generally accepted standards, and the tailoring and the fabric itself leave much to be desired. Therefore, domestic buyers are increasingly paying attention to the products of local factories and cooperatives.

Even at the stage of developing a business plan for a sewing production, you should choose which consumer the products will be focused on. When developing a business from scratch, it is better to give preference to the middle segment - those customers who pay attention to the quality of the thing, and not to the name on the tag. You won't be able to compete with serious brands at the start.

What to consider in a sewing business plan

For the smooth operation of production, it is required to determine the direction of its activities. There are such options:

- clothing is the most popular trend, which includes casual, special, outerwear for adults and children;

- home textiles;

- Stuffed Toys;

- other accessories.

The amount of start-up capital will depend on the volumes prescribed in the sewing business plan. With this in mind, both the number of personnel and the area of the premises are determined. The next step after determining the direction of work of the sewing enterprise will be the registration of an LLC or individual entrepreneur. The list of documents required for this is below.

What documents are required to register a sewing business: table

Compare the list required documents to collect before starting a sewing business:

| SP | Ltd |

| A photocopy of all pages of the passport of a citizen of the Russian Federation | Application drawn up in accordance with Form 11001 |

| Application drawn up in accordance with the P21001 form | Decision to create legal entity(if the owner sewing business one) or the protocol on its opening (if there are several owners) |

| Application for the transition to the simplified tax system (if you plan to keep accounting records for this system), drawn up in the form 26.2-1 | Statutory document of LLC |

| Receipt of payment of the state fee in the amount of 800 rubles | Passports and their copies, notarized (the document must be submitted by all founders) |

| Application for the transition to the simplified tax system (if accounting will be kept under this system), drawn up in the form 26.2-1 | |

| Receipt for payment of the state fee 4000 rubles |

The term for consideration of the application is 5 working days. Then the founders will be invited to the local office of the tax inspectorate, where they will receive a package of documents from an entrepreneur or legal entity. Having received documents for running a sewing business, you should open a company bank account and order a company seal.

The following OKVED codes are used for sewing production:

- textile clothing and accessories - 18.2;

- overalls - 18.21;

- outerwear - 18.22;

- other clothes and accessories - 18.24.

When starting a sewing business, the following key factors should be considered:

- legislative norms regarding industrial premises;

- the required amount of equipment;

- hiring workers;

- the amount of funds that will be required to start a sewing business and monthly expenses;

- analytical data on supply and demand in the market, sales volume and payback.

What type of business to choose at the start: small, medium or large?

Everything manufacturing enterprises, including sewing, are divided into three types: small, medium and large. To start a small sewing business, you will need a room and about 400 thousand rubles for the purchase of equipment and Supplies... Such an enterprise will produce from 25 to 50 units of goods per day.

This type of management business will do entrepreneurs with a limited budget who wish to produce exclusive garments, textiles or souvenirs from their own designs. You can sell such goods at a price higher than the market average, provided that they are promoted correctly.

For comparison, before opening a large-scale garment production, you will need to spend about 5 million rubles, but the daily output finished products will be from 150 to 200 pcs. Such a business will pay off faster, since large production allows you to establish wholesale distribution of goods to large retail chains.

It is imperative to conduct an analysis of the regional market and establish the interests and solvency of buyers. To do this, assess the volume of purchases on the market in chain stores. It is important to determine in advance the assortment of goods based on the needs of the target audience and your own capabilities.

Sewing technology

The process of making garments consists of the following stages:

- modeling;

- design, transfer of the finished model to the fabric;

- cutting;

- sewing and finishing.

A certain specialist is responsible for each of the stages. The designer creates the appearance of the future product: draws a sketch, selects fabrics, colors and designs. The designer turns the sketch into a drawing, where the dimensions of the parts are indicated, the required amount of material is indicated. His responsibilities also include the production of patterns and technical documentation. In a sewing workshop or atelier, the work of a designer and fashion designer is performed by a cutter. He communicates with the customer, takes measurements, makes patterns - prepares the product in accordance with the specified parameters. The cut parts are sent to the table by the seamstress who turns them into a finished product.

Advantages and Disadvantages of the Sewing Business

Like any niche, the sewing industry has its pros and cons that should be weighed before opening a sewing workshop. Among the advantages are:

- the ability to realize creative potential, your own vision;

- constant demand for clothing and home textiles, regardless of gender and age;

- often an average number of competing enterprises, since special skills and abilities are required.

The disadvantages of the sewing business are as follows:

- the need for fairly large investments at the start for the purchase of equipment and raw materials;

- seasonality for the demand for various types of knitwear, which makes it necessary to change the processing lines;

- often the absence of highly qualified specialists (for example, seamstresses sometimes have to train on their own).

At the first stage, the segmenting strategy is optimal, that is, the founder of the business should focus on sewing one type of product. This will allow you to minimize the proportion of defects in the garment business from scratch, and gain a foothold in a narrow niche.

Opening a garment factory or workshop to produce goods for sale

Garment factories manufacture products in small and large batches. They can include one or more product lines. The main advantage of a workshop over a home workshop is the ability to set affordable prices due to large production volumes.

Requirements for the premises

If you decide to open a sewing business, then, last but not least, you should choose a room that is most suitable for organizing production. The area of the workshop is determined by the volume of products. For example, for the manufacture of 100 units of products in one work shift, a workshop with an area of about 70 m2 is required.

When planning to rent a room to open a sewing business, you must obtain a permit to operate. For this, the shop must be inspected by the sanitary and fire authorities. To pass the test, the room must have a fire alarm, fire extinguishers and an emergency exit.

Equipment

Having rented premises for a sewing business, you need to start purchasing equipment. For the successful conduct of this activity, the following units are required:

- sewing machine;

- overlock;

- cutting machine;

- steam generator;

- household iron;

- cutting knife;

- button apparatus;

- racks and tables for employees;

- Consumables.

To purchase the equipment described above, you need about 250,000 rubles. The hardware will cost about 50,000 rubles. These costs should be included in the sewing business plan.

Required personnel

The success of your business will depend 70% on the professionalism of your staff. For medium-sized production, you will have to hire:

- three seamstresses;

- two cutters;

- cleaning lady;

- taker of orders.

At first, you can take over the functions of the receiver. When your garment business takes off, you can hire additional employees - designers, fashion designers, etc. Experts recommend hiring at least 60% of experienced employees. Do not be afraid to hire newcomers - having gained valuable skills in your company, they are most likely to work there for many years.

Labor remuneration can be carried out according to the scheme: rate + interest. This approach will motivate employees to improve themselves and speed up the work process. You can also introduce a system of financial bonuses awarded for certain achievements.

Raw materials and consumables

To purchase high-quality raw materials, it is necessary to carefully study the wholesale offers of fabric manufacturers. When choosing goods for running a sewing business, you need to focus on the parameters "price-quality". It is advisable to conclude direct contracts with manufacturers, since in this case you will be able to avoid suppliers' extra charges, thus reducing the cost of production.

At the stage of studying the sewing business in your region, you should ask questions in professional forums, trying to learn from the experience of successful entrepreneurs. Make new acquaintances, look for more profitable suppliers.

The ideal solution is to find a mentor who will agree to accompany your business. From him you can find out where you can buy high-quality raw materials for production and equipment and how to find customers for marketing products.

What is better to sew

To maintain a successful entrepreneurial activity you need to determine which products are in greatest demand in your area. Try to conduct activities in several directions at the same time. For example, you can combine the production of fabric souvenirs with sewing evening dresses, etc. Moreover, such combinations should not be absurd when the company specializes in the production of hammocks and chiffon shawls.

After selling the first batch of goods, analyze the demand again. Identify your target audience. It is possible that the first experience will force you to reconsider some aspects of doing business. For example, you can change the pricing policy after learning that your the target audience consists of people with low income.

In all regions of our country, there is a high demand for children's clothing. Therefore, this direction in the sewing business can be considered a truly gold mine. However, in order to carry out such activities, you will have to obtain an appropriate certificate.

It is very important to devote considerable time to studying the supply and demand in the market. To do this, you can visit the stores of competitors, looking at what products they produce and what prices they set. To attract buyers, you should not try to steal other people's ideas. Try to use your own developments in business - surprise potential clients originality.

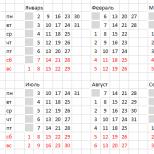

Start-up capital and payback forecast

In order for your sewing business to have a high return on investment, you should calculate all income and expenses in advance. Consider the profitability of a workshop that produces 75 items per day. In this case, the initial investment will be:

- Business registration and execution of all documents - up to 20,000 rubles.

- The cost of renovating the premises is 20,000.

- Rent. Usually paid in two months - the first and the last. It is 60-100 thousand rubles.

- Purchase of materials. Depending on the line of business, it can be from 70,000 to 330,000 rubles.

- Other expenses - 20,000.

Thus, the minimum cost of opening a workshop is about 400,000 rubles. They should be included in the sewing business plan. Now let's look at the monthly expenses, which will consist of the following points:

- Premises rental - 30-50 thousand rubles.

- The salary for employees is 100,000.

- Purchase of materials 70-330 thousand rubles.

- Payment utilities – 15000.

- For transportation costs in a garment business plan, usually about 20,000 are allocated.

The total amount will be from 200,000 to 500,000 rubles.

Knowing the size of the start-up and monthly investments, we can calculate the profitability of the production. For this we need the following numbers:

- One product you make will cost between 700-1500 rubles.

- On average, about 500 units of goods will be sold per month.

- For a month, such a production will receive an income of about 600,000 rubles.

- Thus, the net profit will be about 200,000.

- Payback with such figures is possible within six months after opening a sewing business.

Sales organization

Having opened a sewing business, it is important for you not only to produce products in large quantities, but also to find clients for its sale. Consider what options you have in this case:

- private entrepreneurs;

- Network shops;

- direct sales;

- Internet trade.

Starting a sewing business, the easiest way is to negotiate the sale of products with the owners of small shops. Offer them the sale of your product with a certain amount of extra charge. If your products are popular among consumers, then after some time it will be possible to reach large networks... As a result, you will be able to create an online store that sells your brand.

With the right approach, a garment business can generate a really good income. To do this, you will need to conduct a thorough market analysis, determining the preferences of your target audience. The business is characterized by a quick payback and assumes the possibility of a gradual expansion of production.

Nowadays, the service of individual tailoring is quite popular. This business attracts many entrepreneurs with its small investment and relatively quick payback.

In a previous publication, we touched on this topic, talking about, and. In this article, we will tell you how to open your own atelier from scratch, how much money is needed to organize a sewing business, and what are the payback periods.

Advantages of a tailoring business

- Small investment. You can start your own sewing workshop with just small investment and a keen desire for self-realization. This business is most suitable for people who have certain skills and are proficient in sewing and repairing clothes. But even if you are a complete zero in this field of activity, this does not prevent you from using this business idea;

- The need for exclusive clothing. Today people are very demanding about their outward appearance, including the choice of clothing. It is considered very fashionable to have your own designer who sews clothes according to individual sizes and in limited quantities. Therefore, tailoring services to order are in demand, which means that we can conclude about the profitability of this business area.

How to open a sewing business and what is needed for this?

Let's discuss what it takes to open a tailor shop. It is worth noting that the sewing business is segmented, some open ateliers exclusively for sewing clothes, others prefer to repair products, and still others combine both. Therefore, first of all, you must decide on the direction.

Paperwork

This activity requires legal registration with the tax office. You can choose the material and legal form: individual entrepreneur or LLC. I recommend that you stop at individual entrepreneurship to simplify accounting and tax accounting.

Selection of premises and rent

The number of orders will depend on the location of the atelier. It is advisable to rent a place in a large shopping center. The plus is that in such places there is a constant gathering of people. After purchasing clothes, many people require sewing services (shorten, sew on a thing a few centimeters). But, there are several drawbacks here. The first is the cost of rent, it is quite expensive to rent premises for novice entrepreneurs in elite shopping centers... Secondly, it is competition. As a rule, in many buildings such ateliers already exist, so you have to try to get clients.

Video: How to open a sewing studio Do you need loans ???

Required area. At the initial stage, you do not need a large room, 10-20 sq. m. In this area you will have to fit workplace for a seamstress and a fitting room for clients.

The rental price is quite different, it all depends on the city and the place of rent. Approximately a month, an area of 20 sq. m. will cost you 15-50 thousand rubles.

Purchase of equipment

The main equipment, of course, is a sewing machine, it must be multifunctional. You will also need a special cutting table and sewing accessories such as scissors, needles, threads, and more. The approximate cost of equipment for a sewing studio is from 20,000 rubles.

Sewing workshop staff

It is very important to competently approach this nuance, the success of the whole business depends on the professionalism of your employees. This is especially important at the initial stage, when you have just started to gain the trust of customers.

Requirements for atelier workers. A person must be a professional in his field, that is, have the skills and experience in the sewing business, fulfill orders with high quality and quickly, and be able to communicate with clients. Restraint and accuracy, punctuality and professional performance of work - these are the main criteria by which you need to select candidates for a job.

Wage

I want to say right away that it is quite possible to find a good master who will work for a small salary. So do a good look, don't dwell on the first option that comes across.

The average salary of a seamstress is from approximately 15,000, plus additional work allowances. You can find out the exact figure by analyzing the labor market in your city.

For a start, two seamstresses will be enough for you. They will be able to take orders and carry out small amounts of work. Further, if there are a lot of orders, you can hire additional staff.

Now let's calculate all the costs and profits that you can get by organizing your sewing business.

Video: Custom tailoring: a new niche or a failed idea?

One-time expenses at the tailor shop

Equipment for a sewing workshop. The cost of one sewing machine is from 20,000 rubles, respectively, you need at least two, it will cost from 40 thousand rubles. You will also need furniture - this is a cutting table and chairs, a mirror in the fitting room, and so on. The cost of all equipment is from 50 thousand.

Monthly expenses

- Premises rental - from 15 thousand rubles per month for a room with an area of 20 sq. m .;

- Sewing materials. Consumables such as threads, needles, sewing tools - from 5 thousand rubles per month;

- Salary for seamstresses. If you have two employees, then about 20-30 thousand rubles and more will be spent on wages per month, depending on the prices in your city.

Profits from a sewing atelier

Let's say the average number of orders per day you have 10. If you provide services for the repair of clothes, then the average check amount will be from 400 rubles.

As for individual tailoring of clothes to order, here the cost of the service will be several times more expensive. It all depends on the complexity of the product and the prestige of the atelier.

Therefore, by providing clothing repair services, your sewing workshop will bring you from 100 thousand rubles per month. If we subtract the monthly costs, then the net profit will be from 50 thousand rubles. Agree for a beginner, this is pretty good.

It can be concluded that the sewing business is a profitable business that is suitable for both a novice and an experienced entrepreneur.

I wish you success in all your endeavors.

While sewing at home, many are thinking about opening a full-fledged business - their own atelier or even a sewing workshop. If you are one of those who are interested in the question of where to start sewing production, then this article is for you.

In such an area of business as garment production, competition is quite high, so your production should be favorably distinguished from competitors by excellent product quality and competitive prices. Starting this type of business, it is better to immediately determine your specialization - bed linen, knitwear, or even a specific type of clothing (overalls, winter jackets, etc.).

Drawing up a business plan

Let's decide on the size of the initial costs for opening a sewing workshop:

- equipment from 350 thousand rubles;

- advertising from 50 thousand rubles;

- rent before opening from 40 thousand rubles;

- repair of premises from 70 thousand rubles.

In total, at first you will have to spend from 510 thousand rubles. In addition, monthly expenses are coming, which will amount to:

- staff salaries of 200 thousand rubles;

- rent from 40 thousand rubles;

- materials for work from 350 thousand rubles;

- advertising from 30 thousand rubles;

- taxes.

Every month you will need to spend from 620 thousand rubles. In total, for the first six months of work, you will have to spend at least 1,130 thousand rubles.

Since the above business plan assumes the presence of 10 employees, you can count on 800 thousand rubles of profit every month. Taking into account the fact that the first months of work, after opening a sewing business from scratch, the profit will be less, it can be assumed that the payback period will not come earlier than 6 months after the start of work.

Selection of premises

Before you start a sewing production from scratch, you need to look for a suitable premises. Such premises may be premises of suitable size, located in the industrial part of the city, where the rent is much lower than the cost of rent in the city center.

When choosing the area of the premises, it is necessary to be guided by sanitary standards, which establish that at least 7 square meters should be allocated to each employee.

In addition, the premises for the sewing production should include, in addition to the sewing workshop, an ironing area, a cutting room, a warehouse, a recreation area and a bathroom.

Opening your own sewing workshop attracts by its profitability and return on investment, but it requires a large initial investment and can be created by any sewing master or expert. This business can be started even in a small town, since the demand for clothes is constant and not subject to seasonality. In this article, we will analyze how to create a sewing business from scratch and make it profitable.

Advantages and Disadvantages of the Sewing Business

The best option for garment production would be to focus on the release of one type of product., this will maximize the satisfaction of customers' requirements, establish a technological process and reduce the proportion of rejects. This strategy segmentation is used by companies that are just starting to produce clothing and want to take a narrow market share.

Who is suitable for the sewing business?

The sewing business requires special knowledge and skills, and is suitable for people with sewing skills and experience in this area (1-2 years). If you decide to make a business and are not a specialist, it complicates production and requires time-consuming search for specialists. The first option is preferable because at the very inception of the company, you can fully control all stages of the production of clothing and fully align all business processes. A business will grow faster if it is opened in a city with a population> 500,000, if locality less is an indicator of low market volume and demand. Also, in a small town, it may be difficult to repair sewing machines.

Directions of products of garment production

Sewing production is used for a wide variety of purposes:

Ideal place to start a sewing business

To open a sewing business, an industrial building in the suburbs is suitable, this will allow recruiting personnel from nearby cities with a lower wages rather than in the city center. For production, I will go to cities with a population of over one million: Yekaterinburg, Chelyabinsk, Kazan, Samara, Novosibirsk, Rostov-on-Don, Sevastopol, Irkutsk. Almost every federal district has a large city. Renting a room is the main item of fixed costs, so you should approach the search for a room responsibly. The premises for the business must comply with the requirements of the SES; production should not be located in residential buildings.

The target audience

Assess your business audience. If a clothing repair shop opens, it is necessary that there are 20-30 nine-story buildings nearby: 20-30,000 inhabitants. This will create a constant demand for repair services. If you produce clothes, then the target audience is wholesale suppliers, shops, markets. It is important not only to engage in production, but also to create a sales network of products. To do this, conclude preliminary agreements with interested customers.

A preliminary assessment will allow us to estimate the required volume of future products. As a rule, clothing repair is in great demand rather than tailoring it in a 60/40 proportion.

Registration of sewing production

Let's analyze the different forms of doing business in the table below.

| Business organization form | Benefits of using | Registration documents |

| SP ( individual entrepreneur) | This form is used to create a sewing workshop when the number of staff is 5-10 people. |

|

| LTD ( limited liability company) | This form is used to create an industrial workshop for the production of clothing, hiring employees, and is used to scale and attract debt capital (loans). |

According to the law, the authorized capital of an LLC cannot be less than 10,000 rubles! |

Registration decision individual entrepreneur(IP) and LLC is accepted tax office within 5 working days. For the sewing industry, the following activity codes are used:

As a rule, the following OKVED codes are chosen for garment production:

Business start-up costs

The main administrative costs for the opening are the production of a seal (~ 2500 rubles). When starting a sewing business, prepare to invest a certain amount of money. Financial resources will be needed to purchase equipment, consumables (fabrics, accessories), pay salaries to employees. It is better not to skimp on materials and equipment, since low-quality goods are not in demand among buyers.

Master class: "7 steps to open the sewing business"

The main equipment for the sewing business

For the mass production of clothing, the following equipment will be required: sewing machines (Brother, Juki, Pegasus, Golden Wheel, Joyee); circular cutting knife; industrial ironing board with a steam generator; one-needle loop semiautomatic device; industrial overlock; button machine. The figure below shows the main types for garment production.

Main Equipment for Garment Manufacturing

The table below shows the cost of purchasing basic sewing equipment. The average cost of the equipment will be 230,000 rubles, the cost of purchasing fabrics will be 50,000 rubles.

Staff recruitment

For recruiting, you can use the following free bulletin boards: avito, irr, professional forums - this will save on the costs of searching for specialists. It is necessary to take employees who have more than 2 years of work experience (do not take students!). Own knowledge technological process production will allow you to select the necessary personnel. To motivate staff for high-quality work, you can add a percentage of product revenue to the base salary. At the initial stage of the business, the main workers are seamstresses, while scaling the business, fashion designers and sales managers will be required.

Business revenue

The average check for repairing clothes is 200 rubles, for sewing 500 rubles. Revenue per month ~ 100,000 rubles, which allows you to recoup the initial costs in ~ 6 months.

Assessment of business attractiveness by website magazine

| Business profitability |      (3.0 out of 5) (3.0 out of 5) |

Business attractiveness

|

| Payback of the project |      (4.0 out of 5) (4.0 out of 5) |

|

| Ease of business creation |      (2.7 out of 5) (2.7 out of 5) |

|

| The strong demand for knitwear makes this business attractive for manufacturing. The disadvantage of the business is a small margin on the sale, as a result, the payback period of the initial costs is 6-12 months. To open a sewing business, you need specific expertise. Business does not require large initial financial investments and is suitable as a micro home business. | ||

* Calculations are based on average data for Russia

Clothing is one of the most sought-after commodities no matter what happens in politics and economics. Clothes are what we need every day along with food and shelter. In difficult years, the consumer can limit himself to the necessary minimum in clothing, as well as increase the duration of its use. However, a person simply cannot completely refuse to use it. This applies, of course, only to everyday clothing (or, according to the generally accepted industry classification, household products). In addition to her, as we know, there are also special-purpose clothing: overalls, uniforms, sportswear, etc. The demand for each of these categories is determined by a number of completely different factors. The production technology, depending on the group in question, may also differ significantly.

Each class is also divided into five groups according to operating conditions:

Outerwear;

Light dress;

Linen and sewing haberdashery;

Hats;

Inventory, equipment and other items.

The best balance of demand and profitability - among household products - is, perhaps, possessed by a light dress. Here, its diversity also plays a role - for men, these are shirts, vests, jumpers, jackets, trousers, jeans; for women - blouses, sweaters, pullovers, cardigans, skirts and trousers and much more. Also here great demands are made on the design of the product. And the wardrobe of a light dress is updated with high frequency, including due to seasonality.

On the other hand, just because the demand for casual clothes is high, the competition in this area is very tough, and constantly changing trends in world fashion adjust this demand towards one or another manufacturer. And manufacturers have to adjust their assortment in accordance with fashion trends. Survival is the one who manages to do it quickly, efficiently and without significant financial losses.

In general, manufacturers of household garments can be roughly divided into two categories according to the method of generating profits.

Earn up to

RUB 200,000 a month having fun!

Trend of 2020. Intelligent entertainment business. Minimum investment... No additional deductions and payments. Turnkey training.

1. By promoting your own brand... The brand owner develops the design and construction of the product, manufactures it and independently promotes it on the market. At the same time, he can use both his own labor and intellectual resources, and outsourced specialists, contractors. The brand brings together a wide range of products, which are distributed through our own retail stores, wholesalers or franchisees. The advantage of this form of business is a higher rate of return; the difficulties include high risks in the development and promotion of the brand.

2. By concentrating on our own production. As a rule, such organizations act as contractors for sewing batches of garments on a tolling basis. They can only have a highly specialized production line - knitwear, textiles. Or they can have a full cycle production, from design to packaging. Profitability in this case is ensured by the absence of costs for maintaining the brand - advertising costs, costs of maintaining a large sales department or a network of retail stores.

A different situation is observed in the workwear and uniforms market. Design and world fashion hardly have any influence here; here functionality and usability rule. Requirements for such products, as a rule, are set by the customer and directly depend on their purpose. With regard to demand, it is determined in most cases by the situation in the relevant market, its ability to pay. A feature of these areas is that the demand for products is usually formed in large batches, purchases are carried out through tenders and competitions. This provides the manufacturer, on the one hand, with a long-term workload, and on the other hand, it reduces the profitability of the business in comparison with household products.

So, if you are thinking about getting into the production of clothes, the first thing to decide is whether you want to develop your own brand, receiving satisfaction from publicity and social recognition, or whether you just want to make money by focusing on the production process. In the first case a prerequisite will be the presence of its own designer (designers), laboratory for experimental tailoring and a talented marketer; it is highly desirable to have designers and technologists, but not necessary - their work can be outsourced. Own production capacity may be minimal, but in this case it is necessary to competently establish relationships with contractors. In the second case, depending on the planned volume of activities and available investments, you can limit yourself to a good technologist who will perform the functions of a production manager, or you can form a full staff production department: designers, technologist, cutters, etc. In subsequent calculations economic efficiency this line of business, we will take only a production line with a staff of seamstresses and a production manager as a base. Additional work and services will form the added cost of tailoring.

Working with your own brand implies, in most cases, positioning on the market of household goods or sportswear. Less often - in the workwear market. The popularity of a brand or brand in the case of uniforms and workwear, especially when participating in tenders, is practically irrelevant. Therefore, the production of such categories of garments will rather be the lot of the second group of enterprises.

We will begin the calculation with this option. First you need to find a room. For small (up to 10 people) and medium (10-25 people) factories, the area of auxiliary premises, such as a warehouse, a cloakroom, a place for eating, toilets, engineering and technical staff (at least a production manager), will be approximately equal to the area of the production line itself. ... The area required for the line is calculated based on the type of products produced and the number of employees. So, when sewing light knitwear, one worker accounts for 4-5 square meters; in the production of more complex textiles - already 5-6 sq. m .; well, the production of outerwear will require 6-8 sq.m. per person. These are only approximate figures, in practice, a lot depends on the type of equipment used, the configuration of the premises, and in the end, on the qualifications and skills of each employee. However, when calculating, we will be guided by them.

So, for sewing textiles (it can be both household items and overalls and uniforms) a team of 15 people will need a production area of 75 sq. M. The auxiliary premises will take up the same amount. In total, we get the required area of 150 sq. M. At the current rental price - 75,000 rubles per month. If we are considering creating our own brand, we will need additional premises: an office for administrative staff and sales department; additional areas for warehouses for fabrics, accessories and finished products; showroom. All together this will amount to at least 100 sq. M. or 50,000 rubles.

You can save on production space by entering shift work work - two 12-hour working days and two days off. With a constant output, this will reduce the occupied area, or with a constant area, increase the output.

Another opportunity to reduce rental costs and labor force is the location of production outside the line big city(even if sales will be carried out within it), and in the region. In this way, even thirty percent savings can be achieved.

Subtracting 10% for various losses - sickness, vacation, downtime due to marriage or equipment malfunction, we get 2376 man-hours of working time per month.

Production is calculated on the basis of established time standards - for each product, a strictly defined time. There are industry standards that were widely used during the Soviet era. But over the years, technologies, materials and equipment have changed, but the standards have remained the same. Therefore, today sewing enterprises derive standards independently, based on the characteristics of the premises, equipment and other factors. For newcomers to the industry, the solution may be to borrow standards from experienced market players.

Ready-made ideas for your business

For example, sewing a light dress on a production line can take an average of 0.7 hours, men's or women's trousers - 0.5-1 hour, a textile jacket with and without lining - 1.5-2 hours, respectively. If we proceed from the option of sewing uniform or workwear, then the number of trousers and jackets will be the same, and the time spent on the product can be averaged up to 1 hour. If the production of light textiles is planned, the time costs will be reduced to 0.5-1 hours per product; if you add light knitwear to the assortment, this figure can be reduced to 0.3 hours. Everything will depend on assortment matrix- the share of this or that product in the total assortment.

So, when sewing uniforms, the monthly output will be:

Today, the average market cost of tailoring trousers is 200 rubles, a textile jacket of a simple cut - 300 rubles; we take 250 rubles as a calculated value. Monthly revenue will be:

Since in the considered option the material (fabric, accessories, threads) is provided by the customer, the cost of purchasing it is not taken into account. However, it is necessary to say about the following nuance: a give-and-take basis is assumed in the customer-contractor relationship, but not customer-supplier, as in the case, for example, with a tender conducted by the department. In this case, the manufacturer purchases the material at his own expense and on his own.

As for the equipment, there are no problems with its purchase today. You can buy both new and used equipment in any volume. The best combination of price and quality is possessed by Japanese sewing machines and overlocks, for the cutting site you can choose knives (for large volumes - cutting-tape machines) made in Poland and China. The cost varies in the widest range - from 650,000 to 20,000 rubles for a new car with a drive. Therefore, it is necessary to carefully determine the assortment, production volumes, prospects for expansion and modernization, and only then proceed with the selection of equipment. It is best to contact the supplier for the selection of the kit. For our design option for the purchase of sewing equipment, it is advisable to pledge 1.0-1.3 million rubles. A cutting table with a saber knife will cost an additional 35,000 rubles, and with a tape cutting machine - 400,000. Production possibilities can also be expanded by knitting and embroidery machines, but usually such work is subcontracted to highly specialized companies.

The presence in the staff of one or several designers presupposes the presence of a specialized software- sewing CAD, the cost of which reaches hundreds of thousands of rubles. You will also need one or two plotters for printing patterns; a digitizer can also be useful for digitizing them. In the very budget option 200,000 rubles can be pledged for this. It must be remembered that a designer on the staff (and, even more so, several) is beneficial only when the company is constantly developing new models. Otherwise, it is easier and cheaper to turn to familiar specialists or purchase a ready-made pattern base.

If you decide to create a brand of fashionable clothes, you cannot do without a laboratory - an experimental workshop, where trial products will be sewn and refined to the standard. The laboratory consists of 3-5 experienced sewing-tailors provided with high-quality equipment. In the context of equipment costs - 300,000 rubles.

If the company plans to purchase large volumes of various types of fabrics on its own, a grading machine will be needed in the warehouse, which is used to rewind, reject and re-measure material from a roll. The cost of such equipment will average 170,000 rubles. For warehouse finished products with a wide assortment, you will also need standard warehouse equipment - from racks to etiquette printers and data collection terminals, which will cost at least 300,000 rubles. In the case of sewing large batches of typical products, such difficulties will not be required.

At the final stage, it is necessary to equip the office: purchase furniture and office equipment; equip a dressing room and a room for eating. All this will cost 150-300 thousand rubles.

Another important point to pay attention to is product certification. According to the Decree of the Government of the Russian Federation of 01.12.2009 No. 982, items of the underwear group, fur clothing and children's clothing of all categories are subject to mandatory certification, however, the ConsultantPlus system indicates almost all categories of garments as excluded from the list of products subject to mandatory certification. Therefore, it is necessary to promptly clarify the conditions in the local certification body.

Summing up the subtotal, we can sum up the investment costs in the minimum and maximum options. The data are summarized in Table 1.

Table 1. Investment costs

So, as can be seen from Table 1, the order of investment costs can vary widely: from 838,000 in the case of organizing a simple workshop for sewing a narrow range of products and the purchase of budget equipment to 3,702,000 rubles when organizing an enterprise broad profile with a staff of designers and technologists, as well as high-quality equipment. And this is not the final amount - as they say, there is no limit to perfection.

Recruitment is also not easy. Fewer educational institutions provide training in the specialties of a seamstress and a cutter. And a few graduates prefer work in trade and other potentially more high-paying industries... The average age of seamstresses working today is 40 years. Partly for this reason, partly because of the peculiarities of the professional education of working personnel in general, even with a fully staffed team, there is a high risk of production downtime due to absenteeism of seamstresses. Remuneration for this position is piecework; with a decrease in production volumes, seamstresses go to work part-time in other workshops at the expense of time off, sick leave, vacations, etc. Serious sewing production implies a stream organization of labor, i.e. each worker performs one or more specific operations, but does not sew the entire product from start to finish. This gives rise to specialization, and when one employee leaves, there is a risk of stopping the entire flow. To prevent such a situation, it is necessary to have several universal specialists in the brigade, who, if necessary, can take on problem operations.

In-line quality control requires special attention. Operational work is significantly different from that of a tailor, for example, in a tailor shop. She demands high speed and accuracy; if a defect from one seamstress went to the next operation, it may remain unnoticed until the very end of the production cycle, and will be revealed only upon acceptance of the finished product. In the best case, this will lead to complete or partial disassembly of the product in order to eliminate the marriage. At worst - to its complete culling. If the marriage did not arise due to inaccuracy, but due to the incorrect execution of the operation, this can lead to the rejection of the whole batch.

The selection of engineering and technical personnel is also not easy, which should include designers, technical designers, technologist, quality control department controller and production manager. There are not so many universities in the country that train graduates of such specialties, and the popularity of specialties is dramatically falling. The situation is broadly similar to that of production workers. Employers keep qualified specialists with high wages, and a weak designer or technologist can cause a company to suffer serious losses. The conclusion from the above is that the search and selection of production personnel at all levels must be taken very seriously.

The staff of the company and the payroll are shown in Table 2.

Table 2. Staffing table and wages fund

Earlier, we calculated the amount of revenue when fulfilling an order for sewing uniforms, consisting of trousers and a jacket. The revenue turned out to be equal to 594,000 rubles, which fully covers the costs of wages and rent of premises. However, the figure obtained reflects a rather pessimistic scenario - the fulfillment of orders from customer-supplied raw materials in accordance with the customer's requirements, the absence of its own design and sales system, etc.

The development, production and marketing of more diverse and complex products will not only increase the costs of the enterprise, but, to a much greater extent, will increase revenue and profitability.

In the case of creating and promoting your own brand, there are several marketing strategies that can be used both individually and in combination.

Own retail store/ net.

Distribution through third party retail stores.

Own online store.

Third Party Online Marketplaces.

Selling a franchise.

Each of these strategies has advantages and disadvantages. Create your own retail network leads to huge capital investments - opening one store will cost no less than 1 million rubles, and with a new unknown brand it will reach the break-even point in 9 months at best. An online store is a seemingly fashionable and promising thing. But clothes need to be tried on - an opportunity that an online store does not provide. Therefore, it is necessary either to arrange a fitting in the presence of a courier, for which, accordingly, a delivery service is needed, or to give the buyer the opportunity to return the goods. A detailed review of each strategy will require a separate article.

So, the simplest option is to organize a highly specialized sewing workshop focused on sewing large batches. A minimum of capital investments, a minimum of organizational difficulties, but also a minimum profitability. If you have serious investment opportunities, then by organizing not just a workshop, but a sewing production with a name, you can make a profit of 200,000 rubles per month. But it must be remembered: the more complex the production and distribution, the higher the risks.

Denis Miroshnichenko

(c) - portal of business plans and guides for starting a small business

29 people are studying this business today.

For 30 days this business was interested in 54771 times.

Calculator for calculating the profitability of this business